6.8 SWIVEL AIR INLET (74200-12700)

•

Using an Allen key* remove screw

40

and washer

39

.

•

Remove swiveling inlet

38

.

•

Unscrew double male connector

41

from swiveling inlet

38

and remove nylon washer

33

.

•

Using a spanner*, remove drilled bolt

37

.

•

Remove two nylon washers

33

and air inlet block

35

.

•

Remove circlip

97

from double male connector

41

using circlip pliers and withdraw sintered filter

96

.

•

Assemble in reverse order of dismantling.

•

Refers to items included in the 74200 service kit. For complete list see page 13.

Item numbers in bold refer to the General Assembly drawing and parts list (pages 18-19).

6.9 DIFFERENTIAL VALVE

•

Using special flat spanner* unscrew valve locking plug

27

, withdraw and remove spring

104

and ‘O’ ring

29

.

•

Remove silencer

34

using a spanner* and remove nylon washer

33

.

•

Push valve piston

28

out from its housing together with ‘O’ rings

30

,

31

&

32

.

•

Check spring

104

for distortion and renew if required.

•

Assemble in reverse order of dismantling.

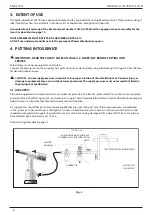

6.10 HEAD ASSEMBLY

•

Remove nose equipment prior to commencing dismantling.

•

Using spanners* remove spindle

44

and locknut

45

.

•

Remove return spring locknut

46

using a spanner*.

•

Remove return spring

47

, washer

99

and locking ring

90

.

•

Check return spring

47

for distortion and renew if required.

•

Assemble in reverse order of dismantling.

6.11 REAR CASING

•

Using an Allen key* remove screw

40

from stroke set finger

88

and lift off bridge washer

95

.

•

Disengage stroke set finger

88

by pushing it back against spring

89

.

•

Unscrew rear casing

86

.

•

Remove rear casing rubber band

87

if necessary.

•

Extract circlip

84

using circlip pliers* and remove sintered silencer

85

.

•

Complete assembly in reverse order of dismantling. Locate pawl

102

in head before screwing on rear casing

86

.

6.12 DISTRIBUTOR

*

Using an Allen key* remove two screws

40

.

*

Withdraw distributor

83

together with air motor end plug

81

and ‘O’ rings

82

&

31

taking care not to drop ball

79

and

push rod

78

.

*

Using an Allen key* remove four countersunk socket head screws

58

and withdraw stroke stop

57

.

*

Pull out two air supply tubes

59

and four ‘O’ rings

60

.

*

Assemble in reverse order of dismantling.

6.13 HYDRAULIC PISTON & AIR MOTOR ASSEMBLY (74200-12610)

•

Wrap adhesive tape around hydraulic piston

54

thread and move assembly backwards slowly and firmly. Using circlip

pliers* remove circlip

52

and front seal

51

.

•

Remove ‘O’ rings

76

and

77

.

•

Using two spanners* separate the hydraulic piston

54

from air motor casing

75

. Shim adjustment ring

55

, movement

pivot

56

and ‘O ring

101

will come out with hydraulic piston

54

.

•

Remove air motor assembly out of air motor casing

75

, remove circlip

61

using circlip pliers*, then tap air motor casing

75

on bench to free components.

• Parts

62

to

74

can be pulled out as an assembly, taking care not to drop pin

74

.

*

Refers to items included in the 74200 service kit. For complete list see page 13.

Item numbers in

bold

refer to the General Assembly drawing and parts list (pages 18-19).

15

ORIGINAL INSTRUC TION

ENGLISH

Summary of Contents for Avdel 74200

Page 68: ...7 OPĆI SKLOPOVI 7 1 OPĆI SKLOP OSNOVNOG ALATA 74200 12000 68 HRVATSKI PRIJEVOD IZVORNIH UPUTA ...

Page 223: ...223 ПЕРЕВОД ОРИГИНАЛЬНОЙ ИНСТРУКЦИИ РУССКИЙ ...

Page 312: ...7 KOOSTEJOONISED 7 1 KOOSTEJOONIS PÕHISEADE 74200 12000 312 EESTI KEEL ORIGINAALJUHENDI TÕLGE ...

Page 347: ...347 ΜΕΤΑΦΡΑΣΗ ΤΟΥ ΠΡΩΤΟΤΥΠΟΥ ΤΩΝ ΟΔΗΓΙΩΝ ΕΛΛΗΝΙΚΆ ...