23

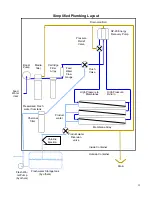

8. Note that the Boost (feed) Pres-

sure sensor and gauge are after

the feed valve so it will only read

when the feed valve is open. The

Boost Pressure should be

about

20 psi (1.4 Bar) during opera-

tion

.

Feed Valve

(shown in RUN position)

If the High Pressure Pump knocks

or bangs, check and adjust the

Boost Pressure, it is either too

high or too low. Adjust the boost

pressure until the pump is running

as smoothly as possible.

To increase or decrease the Boost Pressure rotate

the dial on the Boost Pump Speed Control.

9. Using the buttons on top of the filter housings, bleed

out the air in the filter housings until water is coming

out.

10. Check the brine discharge for water flow. The sys-

tem should fully prime within 60-90 seconds and all

air should be out of the feed water hoses. The pump

should sound smooth.

Note if the Boost Pressure drops below 10 psi the system will alarm “Service Pre-

filters”.

Note: If you must stop the purge sequence for any reason, the control will de-

fault back to the beginning of the purge cycle to protect your system.

New System Start-Up and Testing continued...

Summary of Contents for LB-20000

Page 2: ...2 Page Intentionally blank...

Page 4: ...4 Page Intentionally blank...

Page 48: ...48 Black Parker tube fittings...

Page 49: ...49 John Guest Super Speedfit Fittings...

Page 64: ...64...

Page 65: ...65...