59

STARTING PROCEDURE

________________________________________________________________________________________

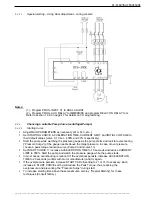

8.4.3.1

Special

starting

±

Using Dual Adjustment

±

wiring scheme

Notes:

(1) - Program PROG. INPUT C1 to DUAL ADJUST

(2) - Program PROG. AUX. RELAY to IMMEDIATE and program RELAY ON DELAY to tx.

Refer

to

section

7.6.9 on page 47 for details on I/O programming.

8.4.4

Choosing a suitable Pump Curve (centrifugal Pumps)

8.4.4.1

Starting

Curve

Adjust MAIN PARAMETERS as necessary (FLA, FLC, etc..)

Set STARTING CURVE, ACCELERATION TIME, CURRENT LIMIT, and INITIAL VOLTAGE to

their default values (curve 0, 10 sec., 400% and 30% respectively).

Start the pump while watching the pressure gauge as the pump starts and look for overshooting

³3UHVVXUH6XUJH´RIWKHJDXJHQHHGOHDERYHWKHWDUJHWSUHVVXUH,QF

ase of over pressure,

choose a peak torque reduction curve (Pump Control curve 1!).

Set START CURVE 1!, increase ACCELERATION TIME to 15 seconds and reduce CURRENT

LIMIT to 350%. Start the pump and watch the pressure gauge while the pump starts.

In most cases, overshooting is reduced. If the overshoot persists, increase ACCELERATION

TIME to 25 seconds (confirm with motor manufacturer) and try again.

If the overpressure persists, increase START CURVE setting to 2!, or 3!, if necessary. Each

increase in START CURVE setting will reduce the Peak Torque, thus, reducing the

RYHUSUHVVXUHDQGSUHYHQWLQJWKH³3UHVVXUH6XUJH´GXULQJVWDUW

7RLQFUHDVHVWDUWLQJWLPHDERYHWKHVHPD[LPXPVHPSOR\³6SHFLDO6WDUWLQJ´IRUWKHVH

techniques (Consult factory).