-

16

-

4. List of Parameters for each Mode

These parameters require configuration in each control mode. Please configure parameters as required.

Refer to

“LECSA Operation Manual (Simplified Edition)”, section 5.3 and “LECSA Operation Manual”, chapter 4

for details.

Refe

r to “LECSA Operation Manual”, chapter 4 for parameters which are not disclosed in this document.

Setup software

(MR Configurator2

TM

: LEC-MRC2E) is necessary for the setting of parameter.

*1 Setup software version 1.52E or above is required.

*2 The setup software (MR Configurator2

TM

: LEC-MRC2E) must be purchased as an additional item.

*3 The USB cable (LEC-MR-J3USB) must be purchased as an additional item.

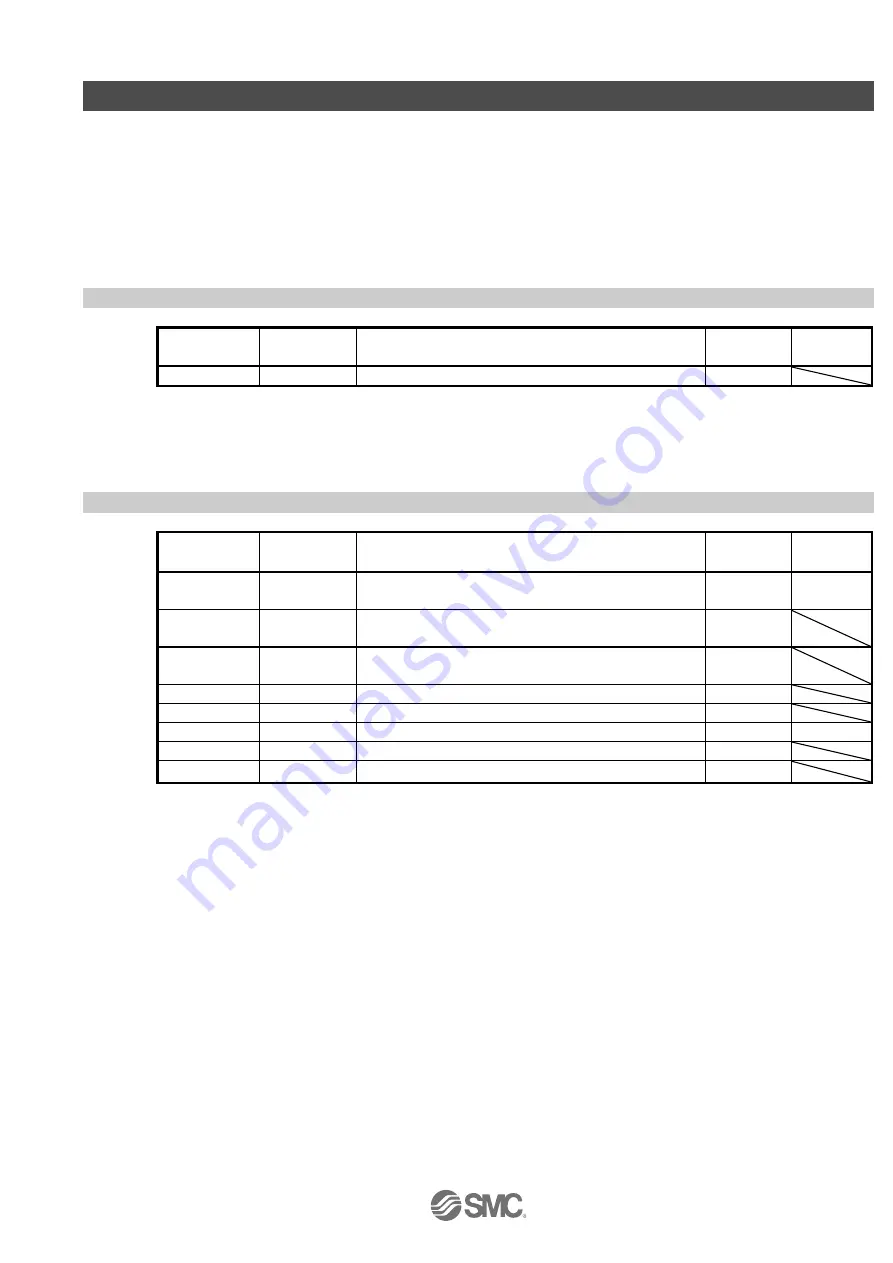

4.1 Parameters common to each mode

(1) [Basic settings parameters (No.PA

□□)]

No.

Symbol

Name

Initial value

Unit

PA01

*STY

Control mode

000h

(2) [I/O setting parameters (No. PD

□□

)]

These parameters are set when changing the input/output signal assignment and switching the input signal

automatic on. See

“LECSA Operation Manual (Simplified Edition)”, section 5.5 and “LECSA Operation

Manual” section 4.4 for details.

4.2 Position control mode

(1) [Basic settings parameters (No.PA

□□)]

No.

Symbol

Description

Initial value

Unit

PA05

*FBP

Number of command input pulses per revolution

100

×100

pulse/rev

PA06

CMX

Electronic gear numerator

(Command input pulse multiplying factor numerator)

1

PA07

CDV

Electronic gear denominator

(Command input pulse multiplying factor denominator)

1

PA08

ATU

Auto tuning mode

001h

PA09

RSP

Auto tuning response

6

PA10

INP

In-position range

100

pulse

PA13

*PLSS

Command input pulse form

000h

PA14

*POL

Rotation direction selection

0