21

3. Installation and wiring

·

The performance of the product varies depending on the surrounding installation and operating conditions. It

is recommended to investigate in advance any processes and parts where static electricity disturbances

occur. Verify that the required conditions have been met in order to effectively remove static electricity before

installation.

·

After installation, verify the performance of this product.

3-1. Installation of Ionizer

3-1-1. Precautions for Installation

·

Be sure to stop power supply and air supply to the product before starting the product installation.

·

Do not affix any tape or labels to the bar. Dielectric phenomenon may occur due to ions arising from such

substances, resulting in electrostatic charging or electric leakage.

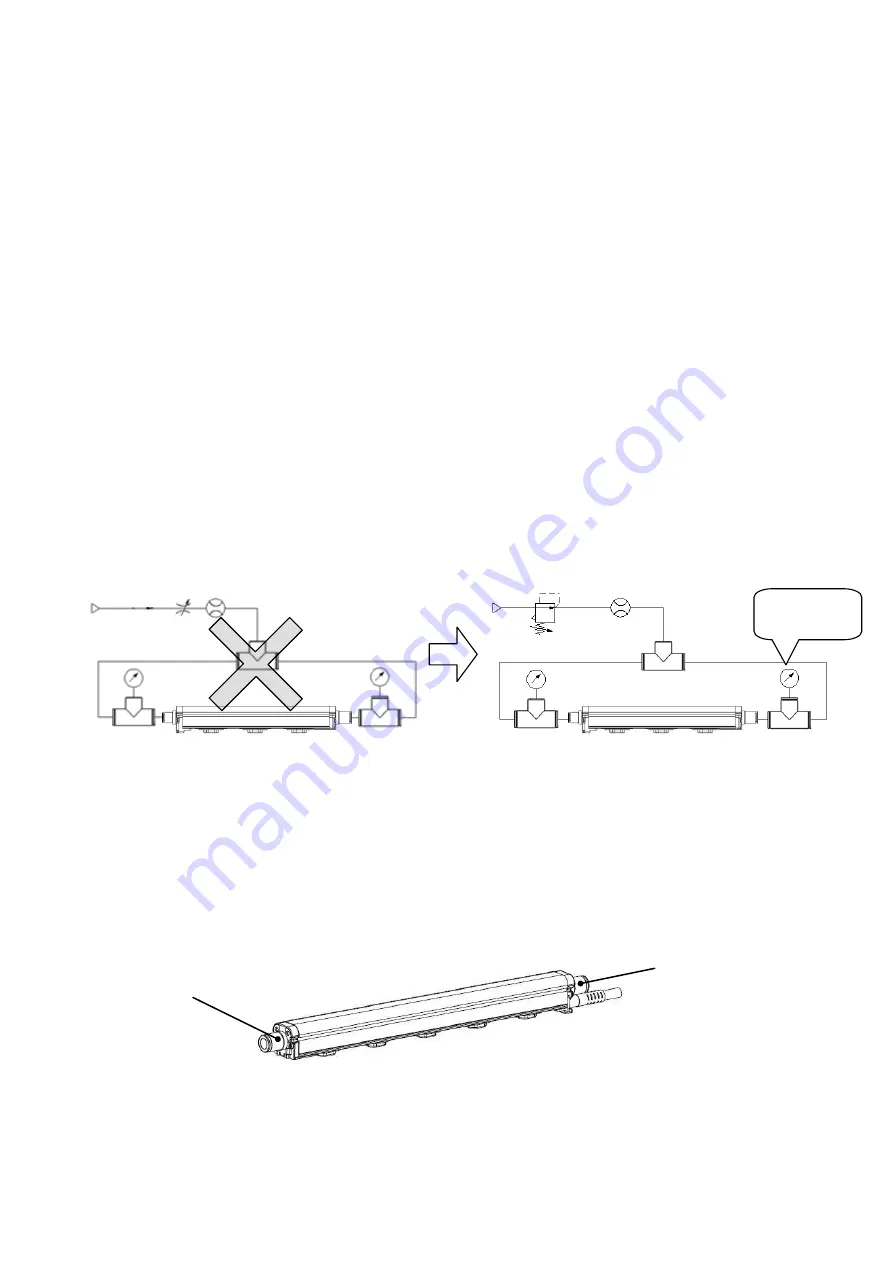

3-1-2. Adjustment of Pressure (Flow adjustment)

·

When air is supplied to the bar, adjust the flow using a regulator which should be connected immediately

before the bar. If a flow adjustment valve is used between the bar and regulator , the speed of the flow from

the nozzle decreases due to the pressure decrease , decreasing the neutralizing performance.

·

Check the pressure around the bar air supply port. A pressure difference may be generated between the

regulator pressure and the pressure at the bar air supply port due to the supply piping length and piping

diameter. If a pressure gauge with regulator is used for checking the pressure, use a large capacity

regulator, keep the piping as short as possible or make the piping diameter larger.

·

When installing a flow meter to the air circuit, refer to “5-4. Flow - Pressure characteristics” to choose the

product type so that the flow of the bar does not exceed the flow meter rated flow range. If the bar's flow

consumption is larger than the rated flow of the selected flow meter, the flow supplied to the bar is limited,

thus deteriorating neutralization performance.

3-1-3. Selection of piping port size

·

When air is supplied, choose the ionizer piping fitting referring to the table7 [Recommended piping port size].

·

Connect piping for air supply through the One-touch fitting(s) either to one end or both ends depending on

the bar length.

·

If a tube is used which is thicker than the recommended tube, neutralization performance will be deteriorated

due to a shortage of air flow.

Piping port

Piping port

Flow adjustment valve

Bar

Pressure

check

Pressure regulator

Bar

Flow meter

Summary of Contents for IZT40 Series

Page 1: ...Document No IZ OMT0049 B PRODUCT NAME Ionizer MODEL Series IZT40 41 42series...

Page 73: ...High voltage power supply module IZTP40 IZTP41 When DIN rail mounting bracket IZT40 B2 is used...

Page 74: ...High voltage power supply module IZTP42 When DIN rail mounting bracket IZT40 B3 is used...