Basics

3.19 Synchronous operation

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

75

Synchronous motion

When a synchronous axis is synchronized to a master value, the "synchronous" status is

displayed by the parameter "MC_GearIn.InGear" = TRUE as well as in the tag of the

<TO>.StatusWord.X22 (Synchronous) technology object. The following axis follows the

dynamics of the leading axis according to the gear ratio.

The dynamic limits configured on the following axis are no longer in effect in the

"synchronous" state. The speed setpoint output to the drive is limited to the configured

maximum speed of the drive (<TO>.Actor.DriveParameter.MaxSpeed).

If the following axis cannot follow the master value, a following error occurs which is

monitored by the following error monitoring.

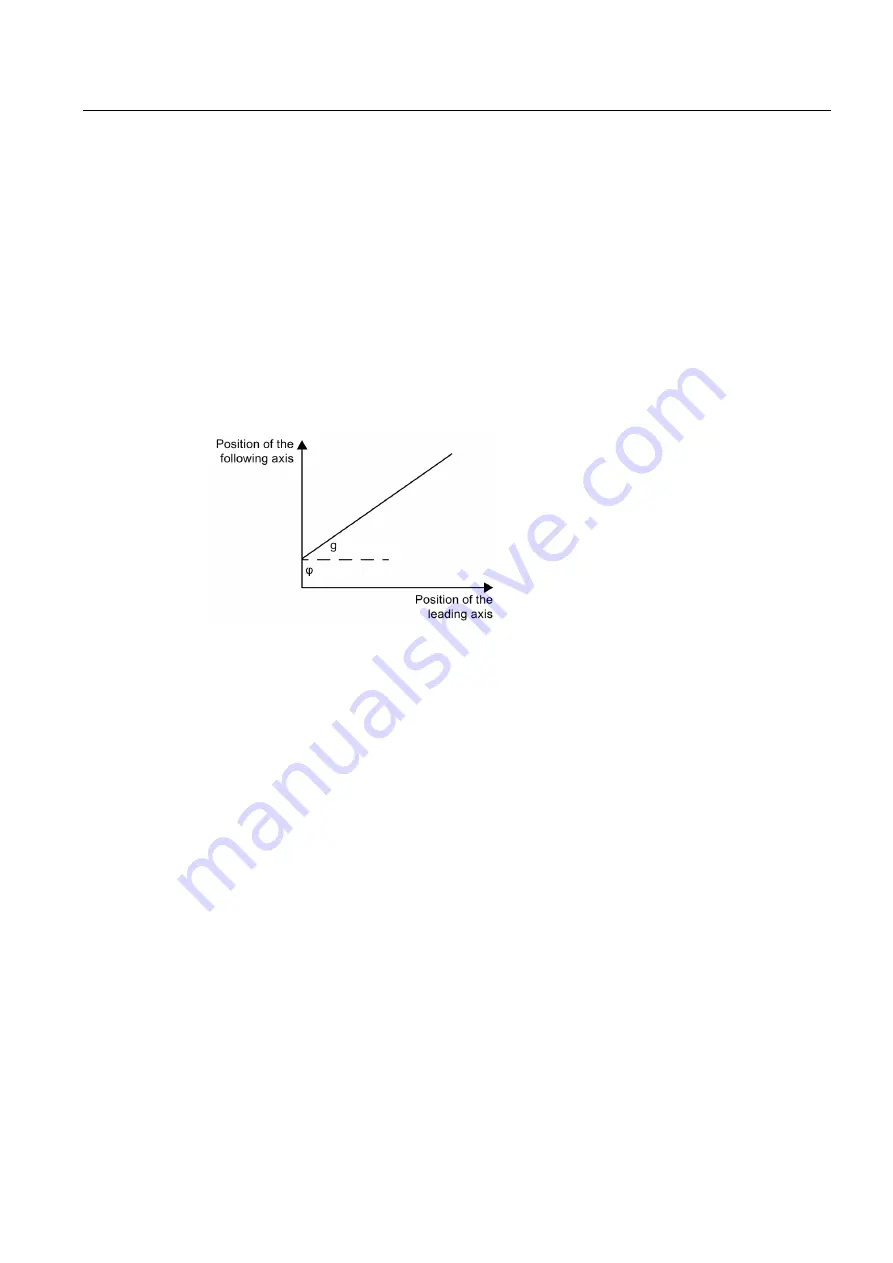

The response characteristic of gearing is expressed as a linear correlation between the

master value and the slave value.

g

Gear ratio (transformation ratio)

φ

Position offset between master value and slave value in synchronous operation

The position offset is derived from the synchronization and is constant thereafter.

The slave value is calculated according to the following formula:

Slave value = g × master value + φ

Overriding synchronous operation

An active synchronous operation is overridden by motion jobs on the following axis.

Direction

The numerator of the gear ratio is specified as positive or negative. This results in the

following response:

●

Positive gear ratio:

The leading and following axes move in the same direction.

●

Negative gear ratio:

The following axis rotates in the opposite direction of the leading axis.