Assembly and Installation

FLOWSIC100 Flare · Operating Instructions · 8013344/11L2/V 2-5/2018-10 · © SICK Engineering GmbH

93

Su

bj

ect

to

ch

an

ge

with

ou

t n

otic

e

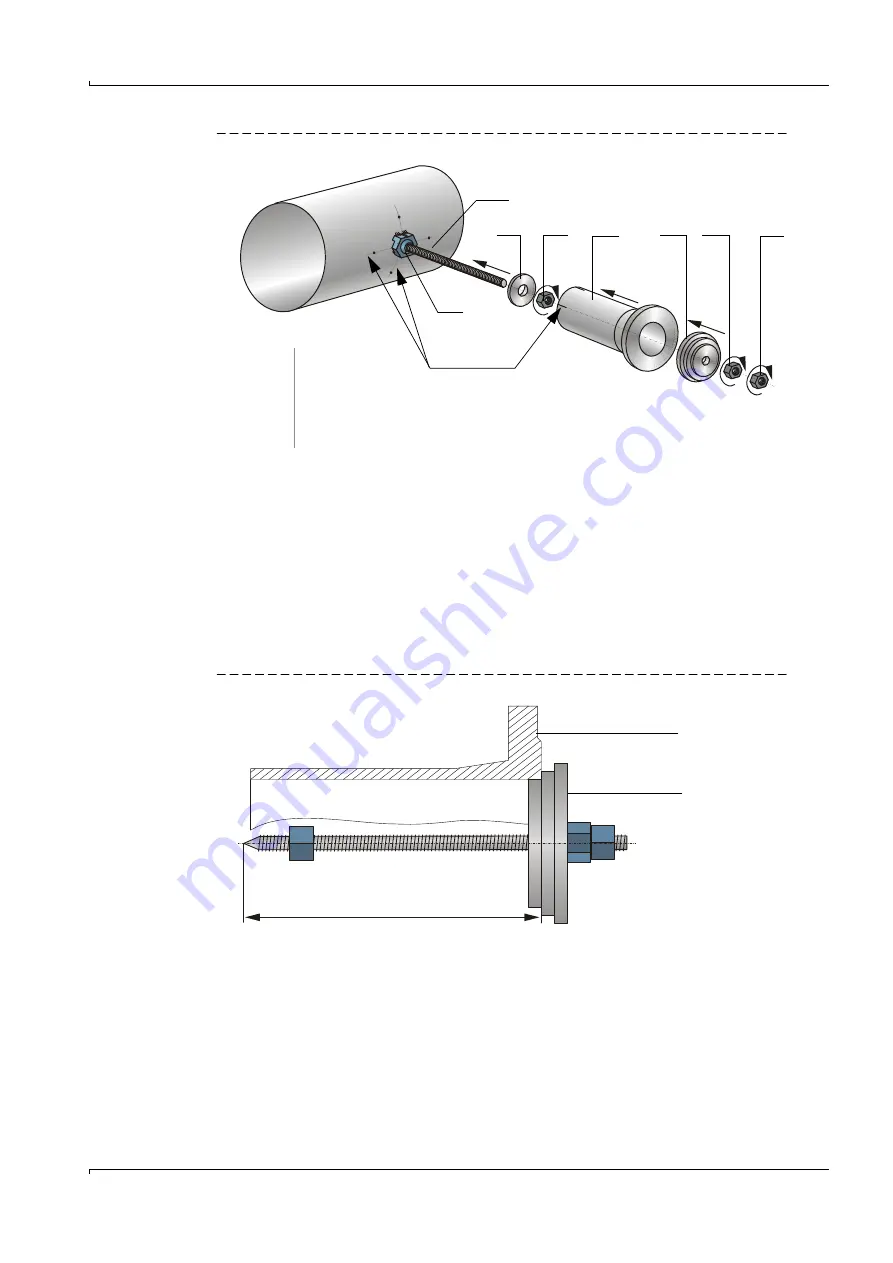

Fig. 41

Fitting the nozzle

Weld the nozzle to the pipeline (seam length approx. 15 mm). Wait at least 1 minute

after each welding to allow the seam to cool down before welding the next point.

Remove uncoated wire.

Remove threaded rod with nuts and centering by turning the counternut (8) against fas-

tening direction. The centering plate will be removed by the clamp ring.

Finish off each weld seam and allow sufficient time for cooling down to avoid unneces-

sary strain on the nozzle and pipe wall.

On FLOWSIC100 Flare cross-duct versions (FLSE100-EX and FLSE100-EXS) and after

sufficient time for cooling down, determine distance D1 between outer pipe wall and

centering.

Fig. 42

Determining of effective nozzle length

On cross-duct versions, weld the nozzle on the opposite pipeline side in the same man-

ner and then determine distance D2.

Marking lines

4 5 6 7 8 9

1

1

Welding aid

4

Centering plate

5

Nut

6

Nozzle

7

Centering

8,9

Counter nuts

10

Clamp ring

10

(Nozzle)

Centering

D1