EB 8310-5 EN

41

Decommissioning and disassembly

9 Decommissioning and disas-

sembly

Risk of bursting in the actuator.

Actuators are pressurized. Improper opening

can lead to actuator components bursting.

Before starting any work on the actuator, de-

pressurize all plant sections concerned and

the actuator.

Risk of personal injury due to preloaded

springs.

Actuators with preloaded springs are under

tension. They can be identified by the long

bolts protruding from the bottom of the actu-

ator.

Before starting any work on the actuator, re-

lieve the compression from the preloaded

springs (see section 9.3).

9.1 Decommissioning

To decommission the actuator for service and

repair work or disassembly, proceed as fol-

lows:

1. Put the control valve out of operation.

See associated valve documentation.

2. Disconnect the pneumatic air supply to

depressurize the actuator.

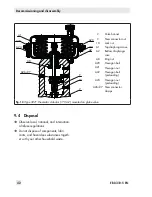

9.2 Removing the actuator

from the valve

1. Put the control valve out of operation.

See associated valve documentation.

2. Undo the clamps of the stem connector

(A26/27).

3. Loosen the stem connector nut (9) and

lock nut (10).

4.

Removing actuators with "stem ex-

tends" action with/without preloaded

springs:

to undo the ring nut (A8), apply

approx. 50 % signal pressure to open the

valve.

5. Unscrew the ring nut (A8) on the valve

bonnet (2).

6. Disconnect the signal pressure again.

7. Remove the ring nut (A8) and actuator

from the valve.

8. Fasten the lock nut (10) and stem con-

nector nut (9) on the valve.

9.3 Relieving the spring com-

pression in the actuator

1. Undo the short nuts (A21) and bolts

(A20) on the diaphragm cases (A1, A2).

2. Undo the the long nuts (A23) and bolts

(A22) on the diaphragm cases evenly in

a crisscross pattern.

DANGER

!

WARNING

!

Summary of Contents for 3277

Page 46: ...46 EB 8310 5 EN...

Page 47: ...EB 8310 5 EN 47...