28

EB 8310-5 EN

Operation

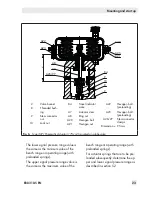

5. Pull the diaphragm plate assembly con-

sisting of the actuator stem (A7), dia-

phragm plate (A5), and diaphragm (A4)

out of the bottom diaphragm case (A2).

6. Clamp the bottom section of the actuator

stem (A7) into a vise using protective

jaws. Make sure that the actuator stem is

not damaged.

7. Unscrew and remove the nut (A33).

8. Remove the parts from the actuator stem

(A7) in the specified order:

−

Spacer (A36)

−

O-ring (A17)

−

Diaphragm plate (A5)

−

Diaphragm (A4)

−

Compressor (A35)

9. Place the parts on the actuator stem

in

the reverse order

as follows:

−

Spacer (A36)

−

O-ring (A17)

−

Diaphragm plate (A5)

−

Diaphragm (A4)

−

Compressor (A35)

Make sure that the seal lip of the dia-

phragm (A4) is inserted correctly be-

tween compressor (A35) and diaphragm

plate (A5).

To prevent the O-ring from being dam-

aged, use a suitable tool to slide the

O-ring onto the actuator stem and to po-

sition it correctly.

10. Screw the nut (A33) against the com-

pressor (A35). On tightening against the

glued hexagon nut (with 175 cm²) or on-

to the slotted nut (with 750 cm²), use a

suitable tool to hold it stationary. Ob-

serve tightening torques. Make sure that

the diaphragm does not turn.

11. Apply a suitable lubricant to the actuator

stem (A7).

A7

A4

A36

A33

A9

A35

A5

A17

A36

A33

A7

A17

A35

A4

A5

A34

A4

Diaphragm

A5

Diaphragm plate

A7

Actuator stem

A9

Nut

A17 O-ring

A33 Nut

A34 Slotted nut

A35 Compressor

A36 Spacer

Fig. 7:

Arrangement of parts for "stem retracts" direction of action (left: 175 cm²; right: 750 cm²)

Summary of Contents for 3277

Page 46: ...46 EB 8310 5 EN...

Page 47: ...EB 8310 5 EN 47...