20

EB 8310-5 EN

Measures for preparation

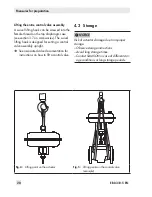

Lifting the entire control valve assembly

A swivel lifting hook can be screwed into the

female thread on the top diaphragm case

(see section 3.7 on Accessories). The swivel

lifting hook is designed for setting a control

valve assembly upright.

Î

See associated valve documentation for

instructions on how to lift a control valve.

4.3 Storage

Risk of actuator damage due to improper

storage.

−

Observe storage instructions.

−

Avoid long storage times.

−

Contact SAMSON in case of different stor-

age conditions or long storage periods.

NOTICE

!

Fig. 4:

Lifting point on the actuator

Fig. 5:

Lifting points on the control valve

(example)

Summary of Contents for 3277

Page 46: ...46 EB 8310 5 EN...

Page 47: ...EB 8310 5 EN 47...