Operator’s manual

Twin-rotor rotary rake

Z2-780; Z2-840

- 33 -

10.

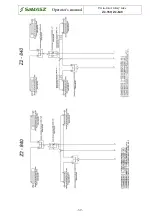

MALFUNCTIONS AND THEIR REPAIRS

Defect

Reason

Repair

The rake does not

lift/lower hydraulically

Damaged or dirty components of

hydraulics

Replace or clean connecting

components of the hydraulics

Damaged hydraulic unit of the tractor

Check condition of hydraulic unit of

the tractor

Damaged lifting cylinder

Replace sealing or other damaged

elements

Leaking cylinder

Dirty oil in hydraulic unit of the tractor

Replace oil in hydraulic unit of the

tractor. Purchase repair kit of the

cylinder and replace damaged sealings

The rake leaves most

part of the swath

Bent tines of the rake or lack of them

Exchange tines

Too low rotation speed

Increase rpm

Wrong height of operation

Regulate operation height according

operator’s manual

Excesive vibration

during work

Damaged PTO shaft

Check the condition of PTO shaft and

if need be replace

Incomplete number of raking arms

Install missing raking arms

Damaged raking tines

Raking arms set too low

Set raking height properly with

adjusting crank or with trolley

(turf soils/ wet meadows / hard

meadows / soft meadows)

Contamination of raked

swath

Raking tines immersed too deep

Set bigger distance between raking

arms and the ground

Twisted raking tines

Replace with new ones

Oil leak in gear

Not tight assembly

Examine tightness and check oil level.

Problem with raking

height adjustment

Soiled or damaged special screw

Clean special screw and if damaged,

replace the screw

Locked or not greased main pin on gear

Remove deposited soiling and then

apply fresh grease

Sheared pin locking the special screw

plate

Install new pin and check adjustment for

smooth operation

It is recommended to lower the gear in the trolley to its maximum after the season is

over

Loud operation of gear

Damaged bearings

Replace damaged elements

Inadequate volume of oil in the box

Check oil level and refill

Carousel-type gear

scraping sound, jamming

Damaged PTO shaft or disc wheel in

gear

Replace damaged elements

Unevenly wearing tyres

on working unit wheels

Bent wheel leg, axle of gear trolley or

longitudinal following plate

Replace elements

Bent steering bar for rake

Correct convergence setting

Twisted PTO shaft tubes,

damaged joint

Not enough overlapping of PTO shaft

tubes

Mount new shaft or provide longer tubes

Plays on shaft joints

Operation with accelerator pedal

Rake is not following the

travel behind tractor

Damaged wheel steering head or bent

steering bars

Replace damaged elements