Operator’s manual

Twin-rotor rotary rake

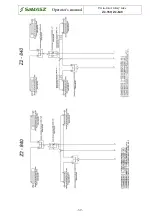

Z2-780; Z2-840

- 29 -

inspect condition of drive wheels and tyre pressure (recommended pressure is given in

Tab. 1

)

,

grease PTO shaft tubes with STP grease,

if necessary, lubricate the parts and units according to lubrication instructions (Chapter 7).

Parts which may cause risk to operator’s health and safety are as follows: damaged rotors, missing

or damaged safety covers, PTO shaft guides, worn or bent tines and holders.

7.2. After-season maintenance and storing of machine

At the end of the season:

the rake should be cleaned, washed and dried. Carefully grease unpainted surfaces and 3-point

linkage pins

remove any traces of rust and paint the area affected,

check lubrication of intersecting axis gears. If leaks occur, remove them immediately,

periodically check the rake and secure the moving parts with grease to prevent the rake from

rust, which affects proper functioning of the rake.

the dismounted machine should be stored in a standstill position (unfolded tine arms together

with rotors, drive chassis set on the ground like in position to work, main frame rest on secured

support stand).

it is recommended to store the set on a paved ground, preferably in dry, roofed places,

inaccessible to unauthorized personnel (mainly children).

if the machine is exposed to weather conditions, apply lubrication regularly.

After longer idle periods:

inspect its technical condition with special attention paid to hydraulic and drive systems,

paint the area affected,

lubricate the parts and units,

inspect condition of drive wheels and tyre pressure (recommended pressure is given in

Tab. 1

)

,

make sure that all nuts and screws are tightened with correct torque (

Tab. 5

),

make sure that all guards are installed in place,

as the storing period is over lubricate the whole machine.

Tab. 5.

Torque values for bolts

In the absence of specific torque values, the following chart can be used as a guide to the

maximum safe torque for a particular size and grade of fastener. There is no torque difference for

fine or coarse threads. Torque values are based on clean, dry threads. Reduce value by 10% if

threads are oiled before assembly.