Chapter 2 Output

B

Allow the job to cure sufficiently (post cure).

As the resin will not have cured sufficiently immediately after printing, light is applied to ensure

sufficient curing. This procedure is known as "post cure." Cure the printed job in the dedicated post-

curing device for at least 15 minutes. Contact your authorized Roland DG Corp. dealer or visit the

Roland DG Corp. website (http://www.rolanddg.com/) to purchase dedicated post-curing devices.

Important

If the base plate resin or the custom tray resin does not cure sufficiently, the job will not meet biocompatibility

requirements.

MEMO

During post cure, the job may become deformed due to the shrinkage of the resin. If precision is required, such as

with frameworks or base plates, deformation can be mitigated by post curing on an abutment. Deformation can

be prevented in any location by applying transparent tape to that location.

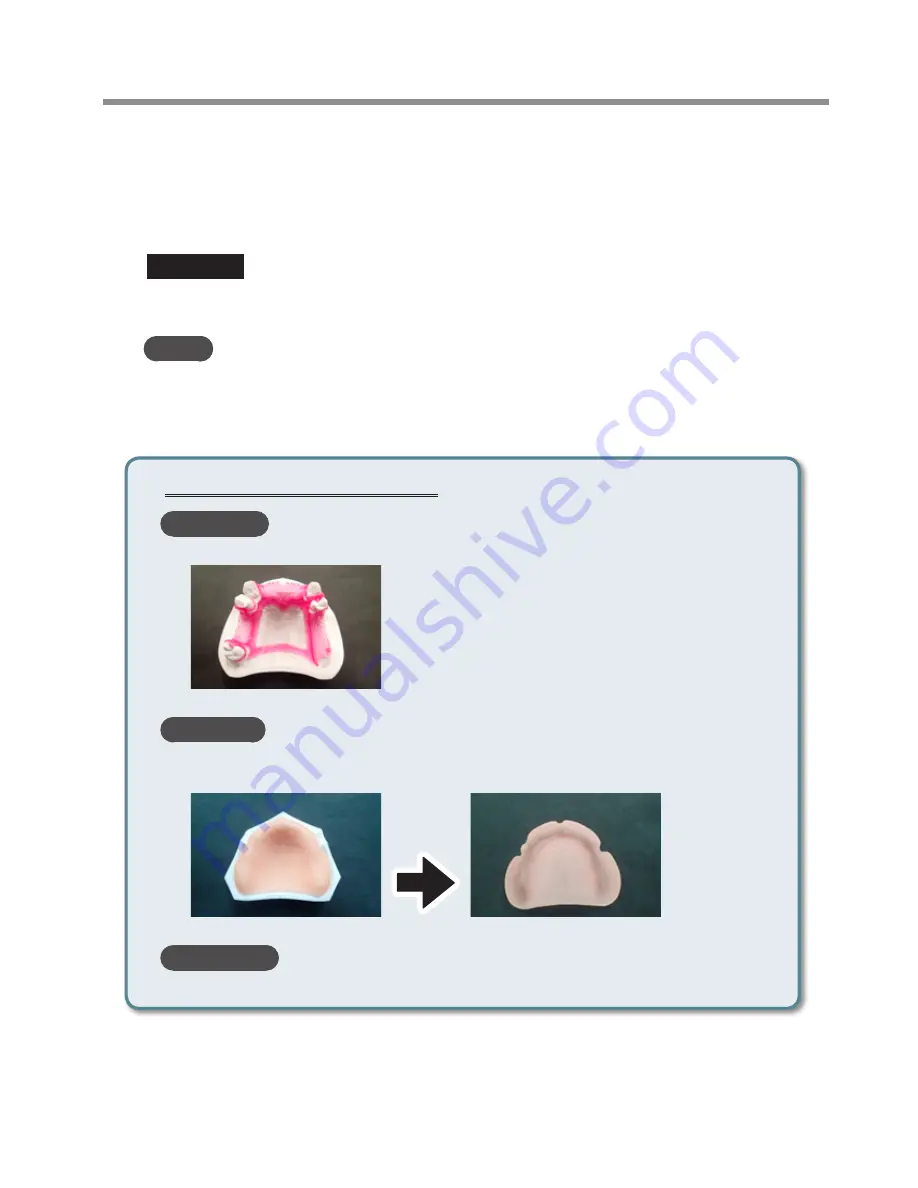

Recommended Curing Times

Framework

About 15 minutes of curing is recommended to ensure the job is fixed to the abutment.

15

minutes

Base plate

Fifteen minutes of curing is performed to ensure the job is fixed to the abutment. Afterward, remove the job from

the abutment and cure for an additional 15 minutes (recommended) or so with the adhesive surface upward.

15

minutes

15

minutes

Custom tray

About 15 minutes of curing is recommended. Ensuring the job is fixed to the abutment is not required.

*

Do not leave resin in the liquid material vat after printing. Be sure to clean the liquid material

vat, printing platform, and work tray.

"

P. 36 "Maintenance after Use"(P. 36 "1. Wash the printing platform.", P. 39 "2. Wash the liquid material vat.", P. 40

"3. Clean the work tray."

3. Printing

35

Summary of Contents for DWP-80S

Page 78: ...R1 161121 FA01081 ...