18

Publication CC-QS015A-EN-P - November 2009

Chapter 1

Product Integration

Time settings are intended to help make sure that only valid objects of the right size, moving

at the right speed, can initiate and maintain a muting sequence.

You may want to add a few seconds to some of your calculations to allow for variations.

Notice that the Connecting diagram shows a lamp, as well as muting sensors connected to

GPIO1 and GPIO2, and that IN1 is labeled Start/Mute override. In this application a Muting

Lamp is required for safety purposes to warn personnel in the area when the light curtain is

muted.

13.

Review the Additional Settings.

a. Make sure that the Muting Lamp monitored box is checked.

Muting lamp monitoring means that should the muting lamp fail, short, or open, the

MSR42 controller will sense it and not initiate or maintain muting. In applications where a

muting lamp is required, generally the muting lamp is required to be monitored.

b. Because you entered a t(mdo) time earlier, leave the Mute dependent override box

checked.

c. In the Muted light curtain section, note that GuardShield Micro 400 is selected and

disabled and make sure that the Light curtain interruption monitored box is checked.

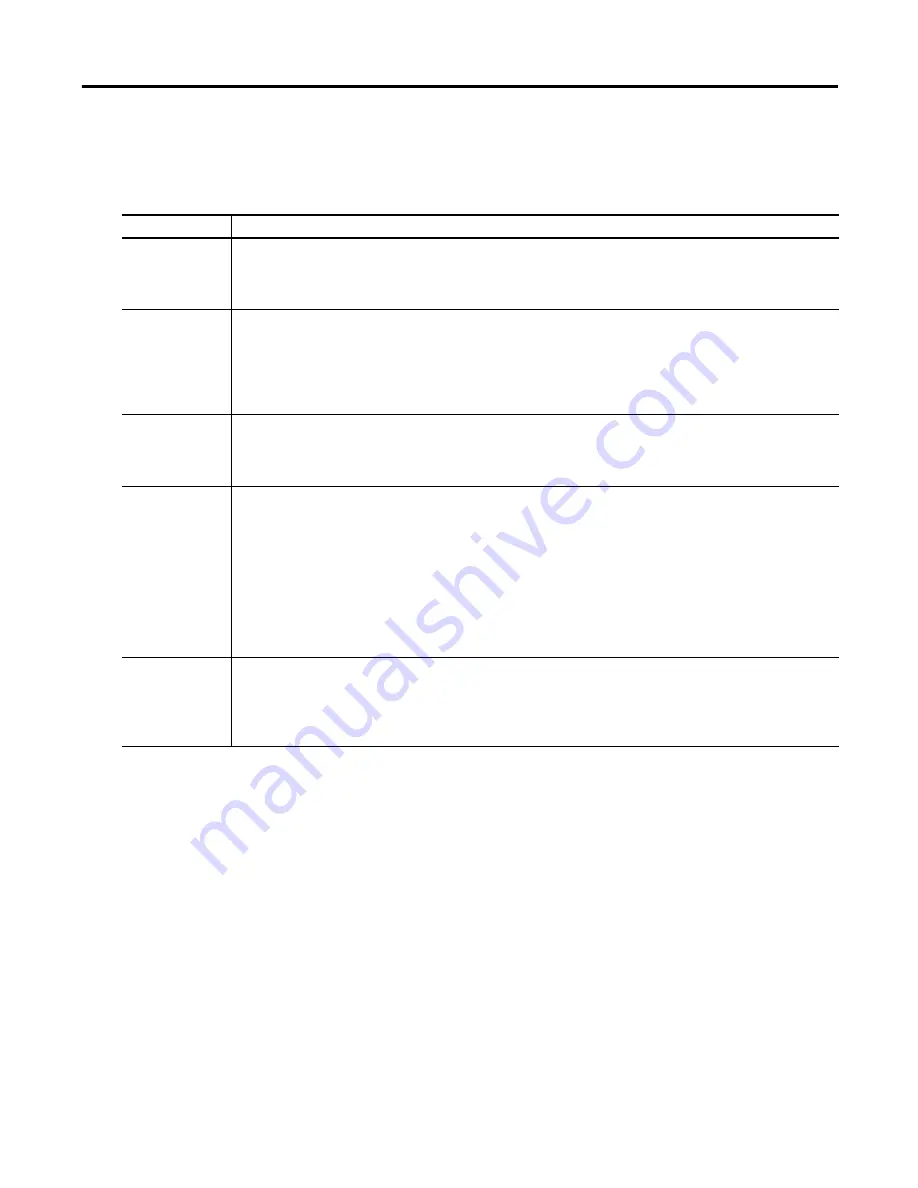

Time Setting

Description

t(sens)

Since both S1 and S2 or both S3 and S4 sensors must be broken simultaneously to initiate a muting sequence,

these sensors should be spaced no further apart than the length of the smallest typical load. Calculate how

long a load takes from the time it first reaches S1 until it reaches S2 (or S3 until it reaches S4), based on the

speed of the conveyor. This is the t(sens) time for your system.

t(espe)

The t(espe) field is disabled until you check the Light curtain interruption monitored checkbox under Additional

Settings. The t(espe) of your system is the time from the moment a load reaches the second sensor (S2 from

the right or S3 from the left) until it enters the light curtain sensing field. Once the light curtain is muted, the

load must interrupt the light curtain within 3 seconds. Therefore, the second sensor must be placed within 3

seconds travel time from the light curtain. t(espe) should be no longer than 3 seconds except in extraordinary

circumstances supported by the risk assessment.

t(mute)

This setting establishes the maximum length of time the light curtain remains muted. Calculate the length of

time it takes the load to travel from the point where it first reaches the second sensor until the trailing edge of

the load leaves the light curtain based on the speed of the conveyor. This is the minimum t(mute) for your

system, which is entered in minutes.

t(mdo)

This setting establishes the maximum length of a Mute Dependent Override. Occasionally, a load may stop

within the light curtain sensing field. It may be difficult to move the load past the light curtain sensing field

with a safe stop in effect. Mute Dependent Override is a function that lets a safety stop be paused and muting

to be re-initiated for the duration of the t(mdo) setting, which lets the load move beyond the light curtain

sensing field. As soon as the load moves past the light curtain sensing field, muting ceases. If the hazardous

area is in clear view of the operator and no personnel or objects are in the hazard area, Mute Dependent

Override can be initiated, in this case, by pressing and releasing the Start/Reset button. Calculate the time it

takes the load to travel from the point where it first reaches the second sensor (S2 from the right, or S3 from

the left) until the trailing edge of the load leaves the light curtain sensing field, based on the speed of the

conveyor.

t(msdel)

In some instances, loads may have gaps that the first two sensors might sense through as the load passes.

This could lead to a muting error. One method to avoid such errors is to delay the sensors’ response to allow

for seeing through gaps. The t(msdel) configures that delay time. Unless the gap is very long or the load is

moving very slowly, the gap is present for only a short time. In most instances, the default 0.050 is suitable.

Leave this value set at 0.050.