6 Normal operation

Installation, Use and Maintenance Manual – GAHP-A

33

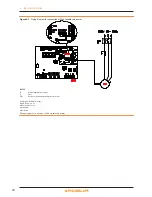

The appliance's electronic board (S61)

Figure 6�1 – GAHP unit electronic board

S61 + Mod10

Display

The 4-digit display of the S61 board (Detail A Figure 6.1 p. 33)

is as follows:

▶

the first digit on the left, green) indicates the menu number

(e.g. "0.", "1.", "2.", ... "8.");

▶

the last three digits (on the right, red) indicate a code or a

value for a parameter, among those included in the selected

menu (e.g. "__6" "_20", "161").

(e.g. menu+parameter "1.__6", "2._20", "3.161").

Knob

One of the following actions may be done with the S61 board

knob (Detail B in Figure 6.1 p. 33):

▶

Enter the menu list (by pressing the first time);

▶

Scroll the menu list, or a series of parameters in a menu (by

turning);

▶

Select a menu or a parameter (by pressing);

▶

Modify and confirm the setting of a parameter (turning and

pressing);

▶

Execute a command (by pressing);

▶

Exit a menu and go back to the higher level by selecting the

letter “E” which is displayed at the end of the menu list or of

a series of parameters in a menu.

The letter "E" is displayed at the end of the menu list or of a series

of parameters in a menu, and indicates the exit to go back to the

higher level by pressing the knob.

Menus and Parameters

The menus may be display only (functional data or parameters),

display and setting (parameters) or control (reset)

Menu for the user (but for the installer and TAC as well)

▶

the menu "0�", display only, for functional data detected

in real time;

▶

the menu "1�", display only, for current values of appli-

ance parameters;

▶

menu "2�", control, to execute flame control unit reset op-

erations, reset errors (Paragraph 6�6 p� 34);

▶

menu "3�", display and setting, to set the value of some

system parameters (e�g� water set point temperature);

the values are initialised by the TAC at First Switch-On�

It is accessed without password�

Menu for the installer or TAC (not accessible to the user)

▶

Menu "4.", "5." and "6." are password-protected. These are

specific sections, exclusively intended for skilled personnel

(installer or TAC). For information see the technical Assistant

Manual.

▶

Menu "7." is display only and intended for the manufacturer.

▶

Menu "8." is empty, it may be selected but not used.

Special key for the knob

▶

To access the menus and parameters of the S61

board, use the special standard supplied key, fas-

tened on the gas pipe above the Electrical Panel.

The key allows the knob to be operated through the

suitable hole in the Electrical Panel cover, operating

safely away from live components.

▶

Always keep the key for future uses.

How to access the Menus and Parameters

Before Starting:

(1) Power supply switch "ON";

(2) Display of the S61 board showing in sequence the

detected water temperature data (if the appliance is in

normal operation), or the flashing malfunction and fail-

ure codes (if the appliance is in failure).

To access the menus and parameters of the S61 board,

proceed as follows (see also Figure 6.1 p. 33):

1. Remove the front panel by removing the fixing

screws.

LEGEND

A

4 digit display

B

Knob

C

CAN port

D

Mod10 controller