26

INSTALLATION

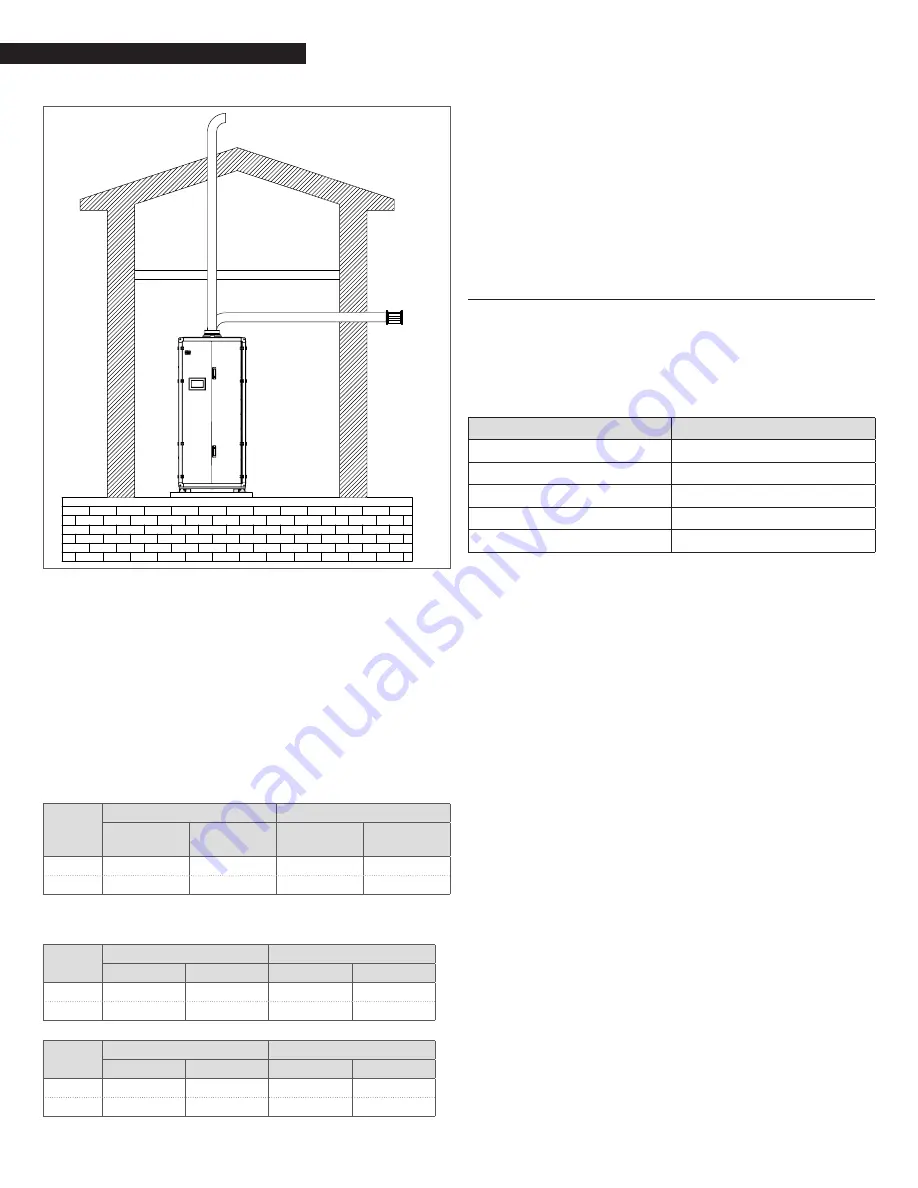

BOILER

EXHAUST

Fig. 35

Exhaust Located on Side Wall

− It is not recommended to terminate vent above any door

or window, condensate can freeze causing ice formations.

− Do not use chimney as a raceway if another boiler or

fireplace is vented into or through chimney.

− Because the unit is capable of discharging low temperature

exhaust gases, the flue must be pitched back towards the

unit a minimum of 1/4” per foot to avoid any condensate

pooling and to allow for proper drainage.

− While there is a positive flue pressure during operation,

the combined pressure drop of vent and combustion air

systems must not exceed the following equivalent length:

Model

PIPE SIZE - 8”

PIPE SIZE - 10”

MAX. equiv.

(m)

MAX. equiv.

(ft)

MAX. equiv.

(m)

MAX. equiv.

(ft)

AR 3000

21

70

30

100

AR 4000

12

40

30

100

Fittings as well as pipe lengths must be calculated as part of the

equivalent length, according to the following table:

Model

45° ELBOW - 8”

45° ELBOW - 10”

equiv. (m)

equiv. (ft)

equiv. (m)

equiv. (ft)

AR 3000

2.1

7

1.5

5

AR 4000

2.1

7

1.5

5

Model

90° ELBOW - 8”

90° ELBOW - 10”

equiv. (m)

equiv. (ft)

equiv. (m)

equiv. (ft)

AR 3000

2.7

9

1.8

6

AR 4000

2.7

9

1.8

6

− For a natural draft installation the draft must not exceed -

0.25” w.c.

− These factors must be planned into the vent installation. If

the maximum allowable equivalent lengths of piping are

exceeded, the unit will not operate properly or reliably.

− For Massachusetts installations, contact companies able

to provide vent systems which conform to all applicable

requirements for installations within the Commonwealth of

Massachusetts.

− For installation of multiple boilers, common venting shall be

sized based on the data of “Appendix H - Venting Size Data”.

4.16

Combustion Air

Air supply is a direct requirement of ANSI 223.1, NFPA-54, CSA

B149.1 and local codes. These codes should be consulted before a

permanent design is determined.

Array boilers can utilize combustion air from the space in which

they are installed, or utilize combustion air ducted directly to the

unit. Ventilation air must be provided in either case.

Material

Standard

ABS

ANSI/ASTM D1527

PVC Schedule 40

ANSI/ASTM D1785 or D2665

CPVC Schedule 40

ANSI/ASTM F441

Polypropylene

ULC S636

Single wall galvanised steel

26 gauge

In cold climates it is essential to provide a motorized air inlet

damper to control the supply of combustion air and prevent

nuisance condensation.

The combustion air must be free of:

− Permanent wave solutions;

− Chlorinated waxes/cleaners;

− Chlorine-based swimming pool chemicals;

− Calcium chloride

− Sodium chloride used for water softening;

− Refrigerant leaks;

− Paint or varnish removers;

− Hydrochloric acid/muriatic acid;

− Cements and glues;

− Antistatic fabric softeners used in clothes dryers;

− Chlorine-type bleaches, detergents, and cleaning solvents

found in household laundry rooms;

− Adhesives used to fasten building products and other

similar products.

To prevent contamination do not connect the combustion air inlet

and exhaust near:

− Dry cleaning/laundry areas and establishments;

− Swimming pools;

− Metal fabrication plants;

− Beauty shops;

− Refrigeration repair shops;

− Photo processing plants;

− Auto body shops;

− Plastic manufacturing plants;

− Furniture refinishing areas and establishments;

− Remodeling areas;

− Garages with workshops

Whenever the environment contains these types of chemicals,

combustion air MUST be supplied from a clean area outdoors for the

protection and longevity of the equipment and warranty validation.

The more common methods of combustion air supply are outlined

Summary of Contents for Array AR 3000

Page 1: ...cod Doc 0079789 rev 5 09 2018 Array AR 3000 AR 4000 US INSTALLATION AND OPERATION MANUAL...

Page 39: ...39 SHUTDOWN 39 APPENDIX WIRING DIAGRAM DEPENDENT 5 6 7 8 RIGHT DOOR...

Page 69: ...69...

Page 70: ...70...

Page 71: ...71...