8.

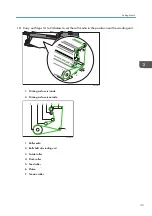

Close the clamp covers at both ends of the roll shaft of the feeding unit so the fixing levers

engage.

M563IC0041

2

1

1. Clamp cover

2. Fixing lever

9.

Center the roll media on the roll shaft of the feeding unit.

M563IC0134

2

1

1. Media

2. Roll core of the winding unit

• When putting the roll core on the roll shaft of the winding unit, align the right end of the roll

core with the right end of the media loaded on the roll shaft of the feeding unit.

• During printing, maintenance is executed periodically to keep the print heads working

correctly. Depending on the loading position of the media, printing may slow down slightly.

• Loading the media at the edge of the platen may cause creasing. If this happens, load the

media at the center.

• The media detection sensors are located in two positions, namely the center and right edge of

the platen, as shown below. Load the media in a position where it will be conveyed above

one or both of the sensors. Printing is possible if the media is detected by one or both of the

sensors. If neither sensor detects the media, an error occurs, reporting that the media has run

out.

3. Basic Operations

42

Summary of Contents for Pro TF6251

Page 2: ......

Page 5: ...Cleaning the Feed Roller 82 Cleaning the Pinch Roller 83 7 Appendix List of Print Modes 85 3 ...

Page 6: ...4 ...

Page 76: ...4 Troubleshooting 74 ...

Page 88: ...MEMO 86 ...

Page 89: ...MEMO 87 ...

Page 90: ...MEMO 88 EN GB EN US EN AU M563 7003A ...

Page 91: ... 2020 2021 Ricoh Co Ltd ...

Page 92: ...M563 7003A AU EN US EN GB EN ...