1

M563IC0150

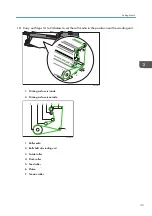

1. Make sure this part is not slack.

If there is any slack, press the media fixing button to unclamp the media and make sure the media is

not adhering to anything. After ensuring that the slack has been eliminated and the media is

aligned properly, repeat Steps 28 to 31.

43.

Click [Media Setting] on the Operation screen.

The Media Setting screen is displayed.

44.

Use the four-way controller (left and right buttons) to move the carriage above the media.

45.

Click [Detect Medium Height].

The medium thickness is detected.

To detect the medium width, click [Detect Medium Width].

46.

Once detection is complete, click [Close].

If "Medium Thickness (T)" and "Medium Width (W)" have been specified manually, click [Apply]

and then click [Close].

47.

Enter the value of the print start position in the "X" of "Print Position" on the Operation

screen.

Check the print start position by referring to the scale on the platen.

The positions of the scale of the roll shaft and the scale of the platen are different. Be sure to use the

scale on the platen as a guide when entering the value.

48.

Adjust the media feed quantity.

See page 58 "Adjusting the Media Feed Quantity".

• If there is media floating on the media sensor, the media may not be detected correctly.

• Depending on the operating environment and media, the machine may not be able to correctly

detect the media width. If the media width is not detected correctly, perform the following tasks:

• Set the media again.

• Check whether outside light is reflecting on the media surface.

3. Basic Operations

56

Summary of Contents for Pro TF6251

Page 2: ......

Page 5: ...Cleaning the Feed Roller 82 Cleaning the Pinch Roller 83 7 Appendix List of Print Modes 85 3 ...

Page 6: ...4 ...

Page 76: ...4 Troubleshooting 74 ...

Page 88: ...MEMO 86 ...

Page 89: ...MEMO 87 ...

Page 90: ...MEMO 88 EN GB EN US EN AU M563 7003A ...

Page 91: ... 2020 2021 Ricoh Co Ltd ...

Page 92: ...M563 7003A AU EN US EN GB EN ...