If this selector is set to "0," the called station starts counting zeros 100 ms after the head of a series

of zeros is detected.

If it is set to "1," the called station starts counting zeros upon detection of 10-ms successive zeros 50

ms after the head of a series of zeros is detected. In this case, if the detection of 10-ms successive

zeros is too late, the data counting period will become less than 1.0 second, making the called station

judge the line condition unacceptable.

• Selectors 2 and 3: Allowable training error rate

The called station checks a series of zeros gathered in training (as described in Selector 1) according

to the allowable training error rate set by these selectors. If the called station judges the line condition

to be accepted, it responds with CFR; if not, it responds with FTT.

• Selectors 4 and 5: Decoding error rate for transmission of RTN

The machine checks the actual decoding errors and then transmits an RTN according to the decoding

error rate (Number of lines containing an error per page ÷ Total number of lines per page) set by

these selectors.

• Selector 8: Limitation of attenuation level

Setting this selector to "0" limits the transmitting level of the modem to 10 dB (1 dB in France).

This setting has priority over the settings selected by WSW02 (selectors 5 through 8) and WSW13

(selectors 5 through 8).

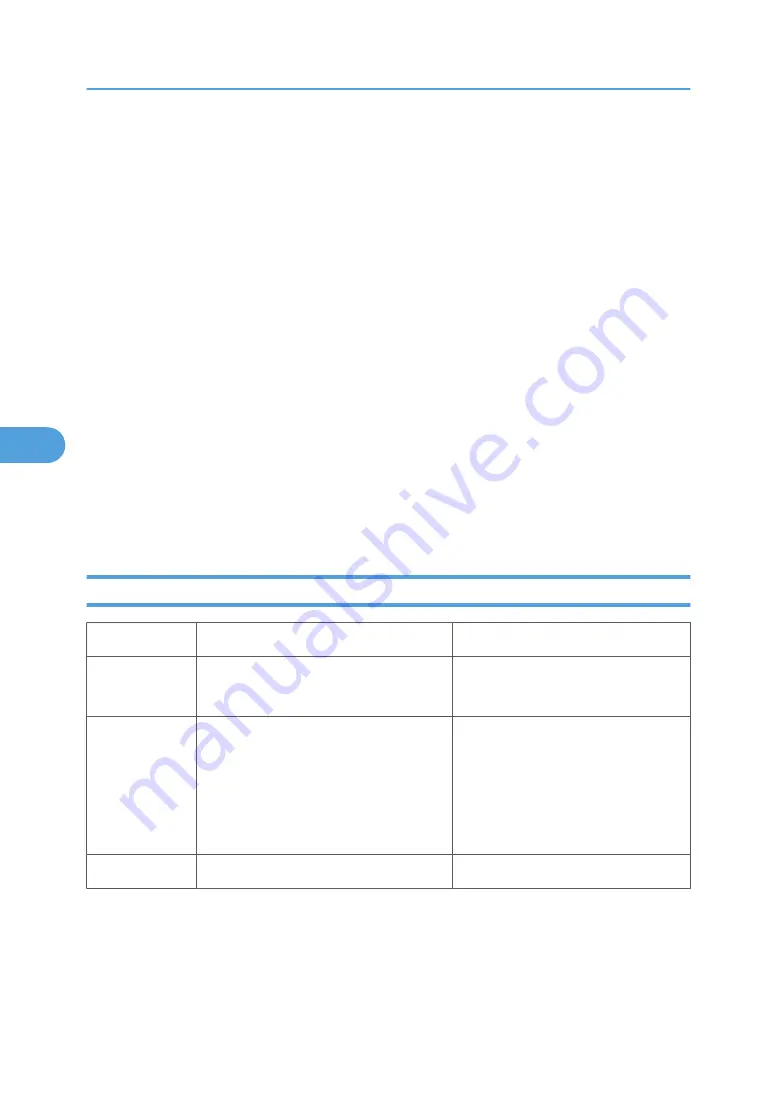

WSW24 (TAD setting 2)

Selector No.

Function

Setting and Specifications

1

2

Not used.

-

3

4

Time length from CML ON to start of

pseudo ring backtone transmission

No. 3 4

0 0 : 4 sec.

0 1 : 3 sec.

1 0 : 2 sec.

1 1 : 1 sec.

5 to 8

Not used.

-

• Selectors 3 and 4: Time length from CML ON to start of pseudo ring backtone transmission

These selectors set the length of time from CML-ON up to the start of pseudo ring backtone

transmission.

5. Service Maintenance

186

5

Summary of Contents for HL-F1

Page 1: ...Model HL F1 Machine Code H558 Field Service Manual 14 May 2010...

Page 2: ......

Page 13: ...1 Product Information Specifications See Appendices for the Specifications 11 1...

Page 15: ...Rear View 12 USB Interface Connector 13 Back Cover 14 AC Power Connector Overview 13 1...

Page 18: ...Components The equipment consists of the following major components 1 Product Information 16 1...

Page 22: ...2 Installation 20 2...

Page 23: ...3 Preventive Maintenance PM Tables There are no PM parts for this machine 21 3...

Page 24: ...3 Preventive Maintenance 22 3...

Page 33: ...Disassembly Flowchart Before You Do 31 4...

Page 44: ...5 Remove the actuator R A from the panel unit B 4 Replacement and Adjustment 42 4...

Page 45: ...6 Release the four hooks to remove the panel rear cover A x 3 B M3x8 Common Parts 43 4...

Page 48: ...11 Remove the rubber key A 4 Replacement and Adjustment 46 4...

Page 60: ...22 Remove the CIS A 23 Disconnect the CIS harness A 4 Replacement and Adjustment 58 4...

Page 61: ...24 Remove the two CIS springs A 25 Remove the LF roller gear A Common Parts 59 4...

Page 63: ...28 Remove the scanning motor F sub ASSY A x 1 M3x6 Common Parts 61 4...

Page 107: ...2 Remove the main frame R A x 3 B M4x12 Main Body 105 4...

Page 110: ...FG harness ASSY 1 Main PCB 2 FG harness ASSY 3 Laser unit 4 Replacement and Adjustment 108 4...

Page 111: ...Regist sensor PCB ASSY 1 PS PCB unit 2 Regist sensor PCB ASSY 3 Chute Harness Routing 109 4...

Page 112: ...Fan Motor 60 Unit 1 Fan motor 60 unit 2 Main PCB 4 Replacement and Adjustment 110 4...

Page 120: ...CIS 1 Main PCB 2 CIS 4 Replacement and Adjustment 118 4...

Page 155: ...10 Click Next Firmware Installation 153 5...

Page 156: ...11 To proceed click Yes 5 Service Maintenance 154 5...

Page 218: ...Image Defects 6 Troubleshooting 216 6...

Page 255: ...Model HL F1 Machine Code H558 Appendices 14 May 2010...

Page 256: ......

Page 258: ...2...