User-Access to The Maintenance Mode

Basically, the maintenance-mode functions listed on the previous page should be accessed by service

personnel only. However, you can allow end users to access some of these under the guidance of service

personnel (e.g., by telephone).

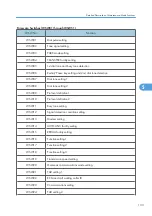

The user-accessible functions (codes 09, 10, 11, 12, 53, 54, 80, 82 and 87) are bolded in the table

given on the previous page. Function code 10 accesses the firmware switches, each of which has eight

selectors. You should not allow end users to access all of those selectors, but you can allow them to access

user-accessible selectors which are bolded in the firmware switch tables in Appendix.

The service personnel should instruct end users to follow the procedure given below.

1. Press the "Menu/Set" [A], "Start" [B] and "Menu/Set" [A] keys in this order.

For the FAX models equipped with numerical keypads, you may press the "Menu/Set" [A], "Start" [B],

and "0" keys.

The "0" appears on the LCD.

2. To access any other function code, call up the desired code using the and [C] keys or numerical

keys.

Then press the "Menu/Set" [A] key.

For function code 10, access the desired firmware switch according to the operating procedure

described in p.160 "Firmware Switches (WSW)".

3. To switch the machine back to the standby state, press the "Stop/Exit" [D] key. When each of the

user-accessible functions is completed, the machine automatically returns to the standby state.

5. Service Maintenance

128

5

Summary of Contents for HL-F1

Page 1: ...Model HL F1 Machine Code H558 Field Service Manual 14 May 2010...

Page 2: ......

Page 13: ...1 Product Information Specifications See Appendices for the Specifications 11 1...

Page 15: ...Rear View 12 USB Interface Connector 13 Back Cover 14 AC Power Connector Overview 13 1...

Page 18: ...Components The equipment consists of the following major components 1 Product Information 16 1...

Page 22: ...2 Installation 20 2...

Page 23: ...3 Preventive Maintenance PM Tables There are no PM parts for this machine 21 3...

Page 24: ...3 Preventive Maintenance 22 3...

Page 33: ...Disassembly Flowchart Before You Do 31 4...

Page 44: ...5 Remove the actuator R A from the panel unit B 4 Replacement and Adjustment 42 4...

Page 45: ...6 Release the four hooks to remove the panel rear cover A x 3 B M3x8 Common Parts 43 4...

Page 48: ...11 Remove the rubber key A 4 Replacement and Adjustment 46 4...

Page 60: ...22 Remove the CIS A 23 Disconnect the CIS harness A 4 Replacement and Adjustment 58 4...

Page 61: ...24 Remove the two CIS springs A 25 Remove the LF roller gear A Common Parts 59 4...

Page 63: ...28 Remove the scanning motor F sub ASSY A x 1 M3x6 Common Parts 61 4...

Page 107: ...2 Remove the main frame R A x 3 B M4x12 Main Body 105 4...

Page 110: ...FG harness ASSY 1 Main PCB 2 FG harness ASSY 3 Laser unit 4 Replacement and Adjustment 108 4...

Page 111: ...Regist sensor PCB ASSY 1 PS PCB unit 2 Regist sensor PCB ASSY 3 Chute Harness Routing 109 4...

Page 112: ...Fan Motor 60 Unit 1 Fan motor 60 unit 2 Main PCB 4 Replacement and Adjustment 110 4...

Page 120: ...CIS 1 Main PCB 2 CIS 4 Replacement and Adjustment 118 4...

Page 155: ...10 Click Next Firmware Installation 153 5...

Page 156: ...11 To proceed click Yes 5 Service Maintenance 154 5...

Page 218: ...Image Defects 6 Troubleshooting 216 6...

Page 255: ...Model HL F1 Machine Code H558 Appendices 14 May 2010...

Page 256: ......

Page 258: ...2...