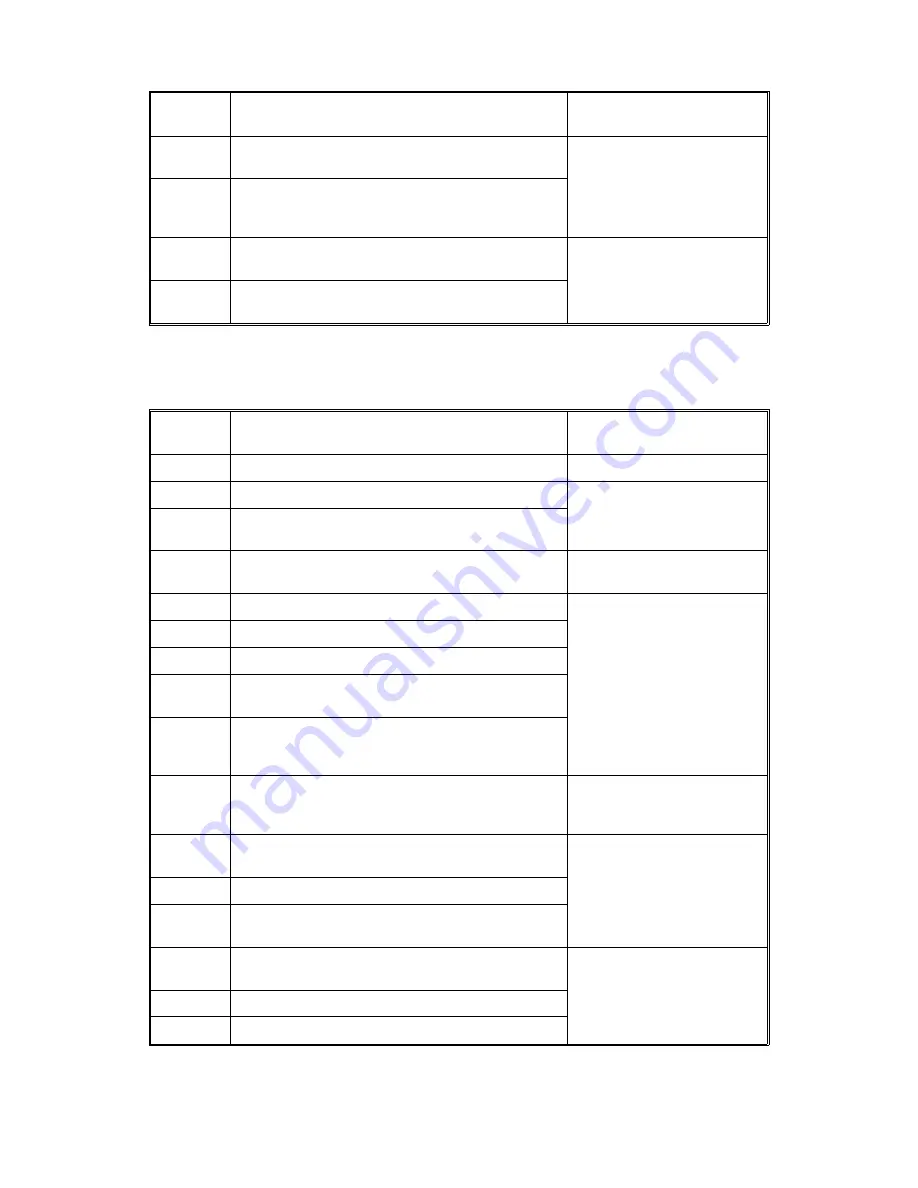

Code

(DJ =)

Cause of Jam

SP Mode No

(Original Misfeed Counter)

40

Recycle gate does not move to down position

when the recycle gate solenoid turns on.

SP47

(Recycle gate/switch back

gate)

41

Switch back gate does not return to the original

position (down position) when the switch back

gate solenoid turns off.

42

Rear original table does not set when the switch

back mode is selected.

SP48 (Others)

99

Original feed clutch stays on longer than 125

seconds.

4.3

PAPER JAM CODE

Code

(PJ =)

Cause of Jam

SP Mode No

(Paper Misfeed Counter)

00

No Jam

—

01

Initial Jam

SP55 (Others)

02

Paper remains in the machine when the Call

Service indicator turns on.

16

Paper entrance sensor (Sheet feeder) ON check.

(When the sheet feeder is used.)

SP51 (Sheet feeder)

17

Registration sensor leading edge OFF check.

SP52

(Manual feed and

registration)

18

Registration sensor ON check.

20

2nd feed sensor leading edge OFF check.

21

Original is not set within 10 second after the

paper is set in the manual feed table.

22

Paper is pulled out after the registration sensor

turns on but before the registration clutch turns

on.

23

Paper entrance sensor (sheet feeder) stays on

when the 2nd feed sensor trailing edge OFF

check. (Multiple feed from the sheet feeder.)

SP51 (Sheet feeder)

24

2nd feed sensor stays on when the registration

sensor trailing edge OFF check.

SP53 (Pick-off)

25

2nd feed sensor ON check.

26

Registration sensor does not turn on when the

registration clutch turns on.

27

Paper entrance sensor (sheet feeder) ON check.

(When the roll feeder is used.)

SP56 (Roll feeder)

28

Loading edge sensor (roll feeder) ON check.

30

Cutter abnormal condition

JAM CODE LIST

31 December 1992

4-46

Summary of Contents for FW830

Page 3: ...SECTION 1 OVERALL MACHINE INFORMATION...

Page 19: ...SECTION 2 DETAILED SECTION DESCRIPTIONS...

Page 68: ...SECTION 3 INSTALLATION...

Page 86: ...SECTION 4 SERVICE TABLES...

Page 140: ...SECTION 5 REPLACEMENT AND ADJUSTMENT...

Page 209: ...SECTION 6 TROUBLESHOOTING...

Page 223: ...74 72 73 76 75 79 85 84 83 82 80 81 86 87 88 77 78...

Page 224: ...90 89...