Database parameters

Size (bits)

Output text

CSV column

Work_time

32

<dd:mm:hh:ss>

Time stamp

Amb_temp

8

<Value>

T_amb

Amb_int_temp

8

<Value>

T_amb_int

Amb_ext_temp

8

<Value>

T_amb_ext

Aux_temp

8

<Value>

T_aux

Cond_temp1

8

<Value>

T_cond

Evap_temp1

8

<Value>

T_evap1

Evap_temp2

8

<Value>

T_evap2

Temp_set

8

<Value>

T_set

Amb_hum

8

<Value>

RH_amb

Amb_int_hum

8

<Value>

RH_amb_int

Amb_ext_hum

8

<Value>

RH_amb_ext

RH_set

8

<Value>

RH_set

RH_Fan

8

<Value>

ExtFanSet

Evap_temp_err

1

EVAP

Error

Cond_temp_err

1

COND

Error

Aux_temp_err

1

AUX

Error

Amb_int_err

1

AMB_INT

Error

Amb_ext_err

1

AMB_EXT

Error

SB_mode

1

SB

Mode

Startup_mode

1

STARTUP

Mode

DEH_mode

1

DEH

Mode

Ice_mode

1

ICE

Mode

LP_mode

1

LP

Mode

HP_mode

1

HP

Mode

Sens_mode

1

SENS

Mode

AmbT_mode

1

AMBT

Mode

AmbRH_mode

1

AMBRH

Mode

Service_ena

1

ENABLED

Mode

The USB interface is used for transferring data logs from the unit to a USB stick.

The unit data is saved every three hours and stored in the internal memory. Switching the status to fault mode

also triggers the storage of data.

If the memory is completely full, the oldest logs are overwritten by the newest logs.

When a USB stick is inserted into the USB interface, all of the logs that have been recorded are saved in the CSV

file “data_log.csv”. The data is the internal memory is not deleted as a result of this process and can therefore

be transferred to several USB sticks.

USB interface

The data log is saved in the form of the following parameters:

30

REMKO SLN Series

Summary of Contents for SLN 45

Page 2: ......

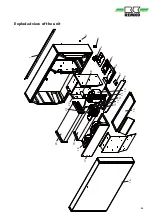

Page 25: ...1 10 2 3 4 5 6 7 8 9 11 12 13 14 15 16 17 18 19 21 20 22 Exploded view of the unit 25...

Page 34: ...Notes...

Page 35: ......