Installation Manual

Combi - cod. 99943NA – November 2002

12

GAS TYPE CONVERSION

Conversion of the boiler

from natural gas to LPG

and vice versa must be

performed by qualified

personnel only.

Conversion is performed

as follows:

a) turn off the main power

switch;

b) close the gas cock;

c) substitute the jets on

the main burner as

follows:

•

undo the gas pipe 5

(fig.1) from the burner

manifold using a size

24 spanner;

•

separate the burner

manifold 2 from the

burner ramps 1 by

undoing the 4 screws 3

using a Philips

screwdriver;

•

fit new jets 4 to the

burner suitable for the

type of gas the boiler

will run on using a no. 7

spanner. The jets must

be fitted with new

gaskets;

•

reassemble the entire burner unit. Use the soapy water method to check for gas leaks each time gas connections are

dismantled and reassembled;

d) change the spring 6 (fig.2) to suit the type of gas used. The spring is located inside the stabiliser in the gas valve 8. To

change the spring, open the fastening clips 2 and, after unhooking the coil 1, remove the modulator core 7 and change the

spring; once this has been done reassemble everything;

e) move the jumper on the circuit board to suit the type of gas (fig.4).

f) replace the gas setting plate that indicates the type of gas and nominal pressure for the boiler. When converting the boiler to

work with a different type of gas, remove the existing plate and replace it with the new one supplied in the conversion kit.

g) calibrate the new max. and min. settings for the modulator.

DATA TABLE

Models:

RSF 20 E

NATURAL GAS G 20

LIQUID BUTAN GAS G 30

LIQUID PROPANE GAS G 31

Lower Wobbe index (15°C; 1013 mbar)

MJ/m3n

45.67 80.58

70.69

Rated feed pressure

mbar(mm c.w.)

20(204) 30(306)

37(377)

Minimum feed pressure

mbar(mm c.w.)

17(173.4) 20(204)

25(255)

Main burner: 13 jets - Ø jet

mm.

1.25 0.75

0.75

Consuption (15°C; 1013 mbar)

mc/h.

2.8

Consuption (15°C; 1013 mbar)

Kg/h.

2.10 2.07

Models:

RSF 24 E

NATURAL GAS G 20

LIQUID BUTAN GAS G 30

LIQUID PROPANE GAS G 31

Lower Wobbe index (15°C; 1013 mbar)

MJ/m3n

45.67 80.58

70.69

Rated feed pressure

mbar(mm c.w.)

20(204) 30(306)

37(377)

Minimum feed pressure

mbar(mm c.w.)

17(173.4) 20(204)

25(255)

Main burner: 13 jets - Ø jet

mm.

1.25 0.77

0.77

Consuption (15°C; 1013 mbar)

mc/h.

3.15

Consuption (15°C; 1013 mbar)

Kg/h.

2.35 2.32

1

2

3

4

5

11

10

8

7

6

9

4

3

1

11

10

2

5

5

13

12

4

7

5

8

6

1

2

3

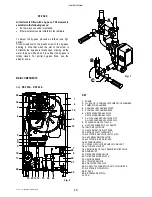

LEGEND

:

1.

Gas valve mod. VK4105A

2.

Pressure modulator

3.

Inlet pressure point

4.

Outlet pressure point

5.

Electronic ignition board

6.

Gas pipe

7.

Burner manifold

8.

13 ramp gas burner

9.

Injectors

10.

Ignition electrodes

11.

Flame ionisation electrodes

12.

Ignition board fastening screws

13.

Ignition board cover

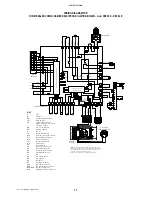

LEGEND

:

1.

Modulating coil

2.

Fastening clips

3.

Min. gas pressure adjustament srew

4.

Max. gas pressure adjustament core

5.

Core lock nut

6.

Calibrator spring (blue natural gas) (grey L.P.G.)

7.

Pressure modulator

8.

Gas valve stabiliser

GAS BURNER UNIT

PRESSURE MODULATOR

Link Jumper on RAMIRE

ciruit board

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Summary of Contents for RSF 24 E

Page 2: ......