Installation Manual

Combi - cod. 99943NA – November 2002

11

BOILER ADJUSTMENTS

SELECTOR

GPL-MET

NATURAL GAS

L.P.G.

SELECTOR

M5

M11

D6

+

C22

CM3

RS1

J16

R48

R2

3

R2

4

FA1

C2

0

C1

9

C7

C6

C2

1

R47

R17

R49

R1

5

R32

C13

41

R16

C14

R5

7

R6

1

R39

R62

M9

J20

C9

C5

+

R38

42

R31

R37

R1

8

IC2

+

R58

R42

ME

T

43

44

GP

L

R41

C26

+

R43

R4

0

C1

5

R5

6

R3

3

R22

45

46

J7

T4

R21

M13

R63

C25

61

D1

2

47

J21

R3

6

R34

48

D4

R5

9

R6

0

59

A

B

60

+

IC4

J10

+

RISC.

P2

J11

C24

TR1

R1

4

R9

R1

1

R7

+

R12

R8

C3

R1

3

C8

J9

+

C1

7

R10

C1

8

C4

+

C2

7

C1

6

R3

0

R2

8

R2

6

J12

M10

40

FASX4

FASX1

R46

IC1

36

R45

J9

38

R44

39

J15

35

37

R5

C1

2

C1

0

R2

0

FASX2

FASX3

R19

+

R3

R6

R1

R4

C11

J13

J18

CM4

M8

R2

34

33

J4

T3

R29

R25

T1

M14

64

+

+

+

J5

P3

M. RIS

P4

P5

T. RIS

RLA

62

63

32

31

D2

D3

RL4-RV

T2

R27

D1

P1 SAN.

RL2-RS

M7

30

29

D5

PTC1

57

CM1

PR

IM

A

R

IE

SECON

D

O

R

IE

52

53

51

49

50

J1

7

J6

D1

1

D1

0

D7

55

56

R5

5

RLA

54

58

R35

D8

IC3

R53

D9

R54

M1

22

RL3-RT

RL1-RP

J2

J4

24

J1

R5

0

23

25

26

28

27

M12

M6

R51

M4

14

15

16

18

19

17

J3

R52

21 20

FUSE 1

2AF

2

3

4

12

11

9

10

8

7

M2

13

C23

6

5

M3

1

SELECTOR

RLA - CM1

LINK

COMMUTATOR

CM3

LINK

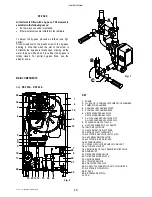

STARTING STEP RLA P4

This trimmer is a slow ignition

regulator and it is calibrated at

minimum during factory test.

Use a small screwdriver for any

adjustments. Turn clockwise to

increase gas pressure to the

burner at start-up (by setting

the trimmer to maximum

calibration pressure of

modulator – see page 16).

Turn counter-clockwise to

decrease gas pressure to the

burner at start-up (by setting

the trimmer to the minimum

pressure at start-up will

correspond to minimum

calibration pressure of

modulator –see page 16).

Through the RLA commutator

you can verify the minimum

gas pressure adjusted to the

modulator. Remove the

commutator from the MET-GPL

selector located on the

RAMIRE 2 circuit board and

insert it on the RLA CM1

selector located on the same

circuit board. Once pressure on

the gauge has been checked,

remove the commutator and

insert it on the MET-GPL

selector.

HEATING TIMER

Delays start-up times of the various ignitions once

the boiler has reached optimum temperature (the

range of adjustment is from 0 to 6 minutes, the

value set during testing at the factory, to 2.5 min.)

Use a screwdriver to adjust the delay time. Turn

clockwise to increase time and counter-clockwise

to decrease time down to zero.

MAXIMUM HEATING TRIMMER.

The trimmer is calibrated at 80% of the

max. rated output during factory testing.

For the first ignition of the boiler, adjust

according to heating power of the

system. Use a screwdriver to adjust it.

Turn clockwise to increase, counter-

clockwise to decrease.

Summary of Contents for RSF 24 E

Page 2: ......