Installation Manual

Combi - cod. 99943NA – November 2002

8

TA

OR

TA

N

L

ye

llo

w

red

5 4

bl

ue

3

2

br

own

1

OR

TA

M

N

L

PT

OR

ye

llo

w

TA

PT

red

5 4

N

L

bl

ue

3

2

br

own

1

OR

TA

TA

PT

M

N

L

BROWN

GIALLO/VERDE

LIGHT BLUE

BLACK

LIGHT BLUE

BLACK

BLACK

BROWN

YELLOW/GREEN

1

2

VT

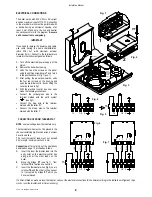

ELECTRICAL CONNECTIONS

The boiler works with 230 V 50 Hz AC current

and has maximum input of 170 W. Connection

to the electrical mains must be performed with

a device having an omnipolar opening of at

least 3 mm. Make sure the live and neutral

connections conform to the diagram.

A secure

earth connection is compulsory.

IMPORTANT

If you need to replace the power supply cable,

use cable having the same characteristics:

(HO5 W-F) 3x1 with maximum external

diameter 8 mm.). Connect to the terminal block

located in the instrument panel as follows:

A. Turn off the electrical power supply at the

mains.

B. Remove the boiler front casing.

C. Undo the two side screws on the panel

using the phillips screwdriver VT and turn it

to the position shown in fig.1 (pos. 1).

D. After pulling the panel downwards, undo

the four rear screws on the housing and

open the electrical control box by lifting the

cover as shown in fig.1.

E. With the electrical control box now open

make the following connections:

•

Connect the yellow/green wire to the

terminal marked with the earth symbol

“ “ (see fig.1).

•

Connect the blue wire to the terminal

marked with the letter “N”.

•

Connect the brown wire to the terminal

marked with the letter “L”.

CONNECTION OF ROOM THERMOSTAT

NOTE

: use low voltage

room thermostats only.

The thermostat wire must not be placed in the

channel containing high tension wires, but must

have its own line

The room thermostat lead must not exceed

50m n length; minimum section 0.5 mm.

Connection

: after carrying out the operations

described on page 15, proceed as follows:

A. Insert the room thermostat lead into the

entry point on the electrical control box

along with all the other leads on the

boiler.

B. Move the bridge

PT

(see fig.1) from

terminal

TA

to the free one next to it.

C. Insert the thermostat wires (fig.2) one in

terminal

TA

and the other in the one next

to it occupied by bridge

PT

which you

have just moved.

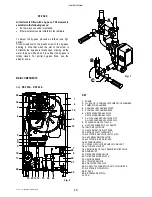

If a timer is fitted as well as a room thermostat, carry out the electrical connections for the timer according to the indications in figures 3 (tipe

clock + room thermostat) and 4 (time clock only).

Fig. 1

Fig. 5

Fig. 4

Fig. 2

Fig. 7

Fig. 6

Fig. 3

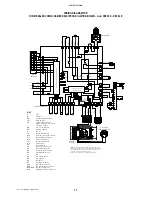

Summary of Contents for RSF 24 E

Page 2: ......