Instruction Book

98

9828 0934 73

Electrical

connection

•

Check that the primary side connections of transformer (T1) correspond with the

supply voltage.

•

See the section

Electric cable size and fuses

for the recommended fuses and cable

size of the supply cables.

•

Check that the electrical installation corresponds to the local codes. The dryer must be

earthed and protected against short circuits by fuses of the inert type in all phases.

•

An isolating switch must be installed near the dryer.

•

The fix speed units are provided with a phase sequence relay. When the dryer does not

start, switch off the voltage and reverse two incoming electric lines.

•

All pipes should be installed stress-free to the dryer unit.

•

All pipes should be installed so that there is no obstruction accessing the unit through the

removable panels.

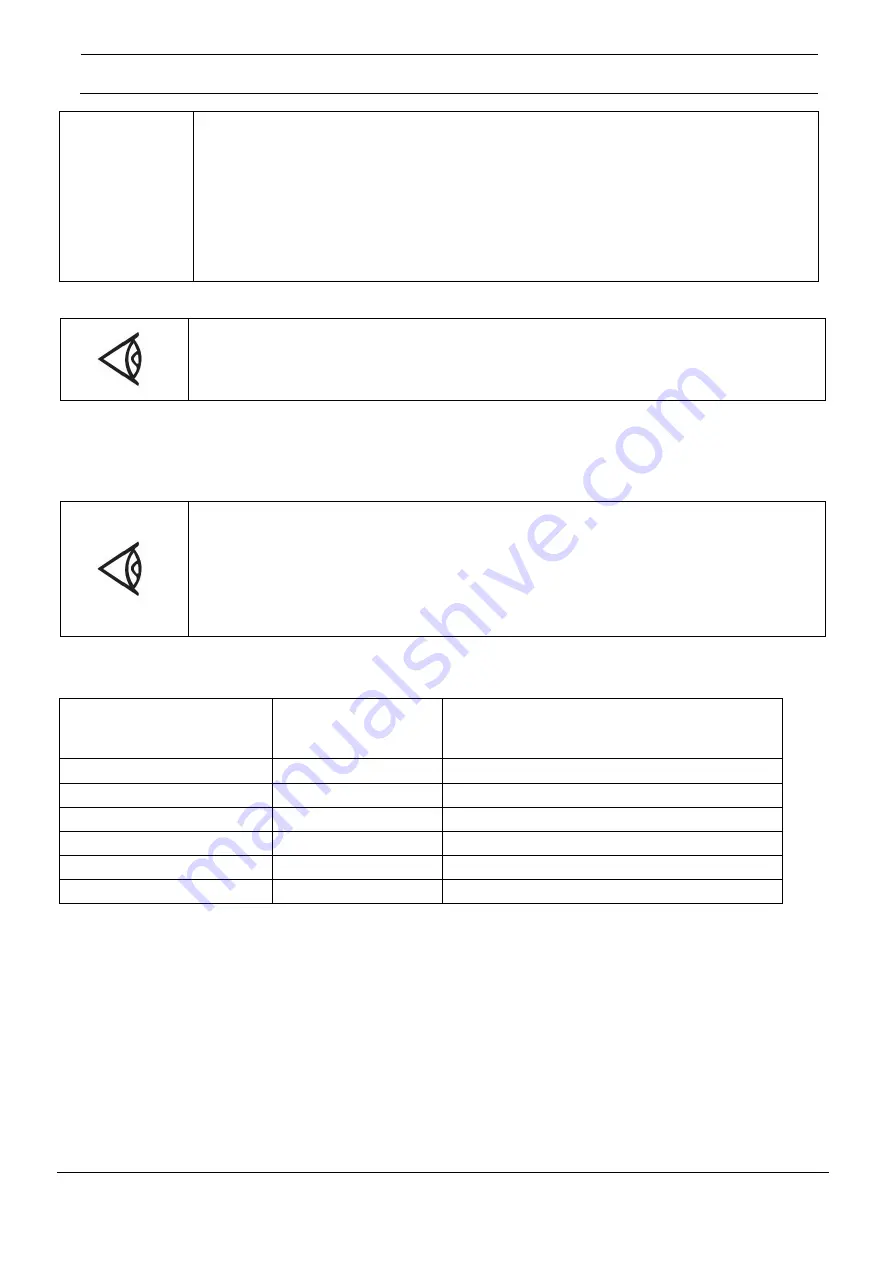

4.4 Electrical cable size and fuses

Important

Local regulations remain applicable if they are stricter than the values proposed.

For 50 Hz dryers, the settings of the main fuses below are according to Directive 73/23/EEC

(low-voltage directive) EN60204, 83/336/EC electromagnetic compatibility. The cable size is

valid for cable PVC 70 ˚C (158 ˚F) at an ambient temperature of 40 ˚C (104 ˚F).

For 60 Hz dryers, the settings of the main fuses below are according to CSA standards C22.2

Nos. 0; 0.4; 0.5; 0.12; 14; 68 and UL508. The cable size is valid for cable 90 ˚C (194 ˚F) at an

ambient temperature of 40 ˚C (104 ˚F).

Fuses

Dryer

Supply voltage

Maximum fuses, recommended type: (CSA)

Class HRC Form II/(UL) Class K5 or RK5

(customer's installation)

QED-650 (

ES 310

)

400 V

3 x 20 A

QED-850 (

ES 410

)

400 V

3 x 20 A

QED-1050 (

ES 510

)

400 V

3 x 20 A

QED-650 (

ES 310

)

460 V

3 x 20 A

QED-850 (

ES 410

)

460 V

3 x 20 A

QED-1050 (

ES 510

)

460 V

3 x 25 A