Description

UM Pallet stacker Prmk10-PS v2.0 EN

23

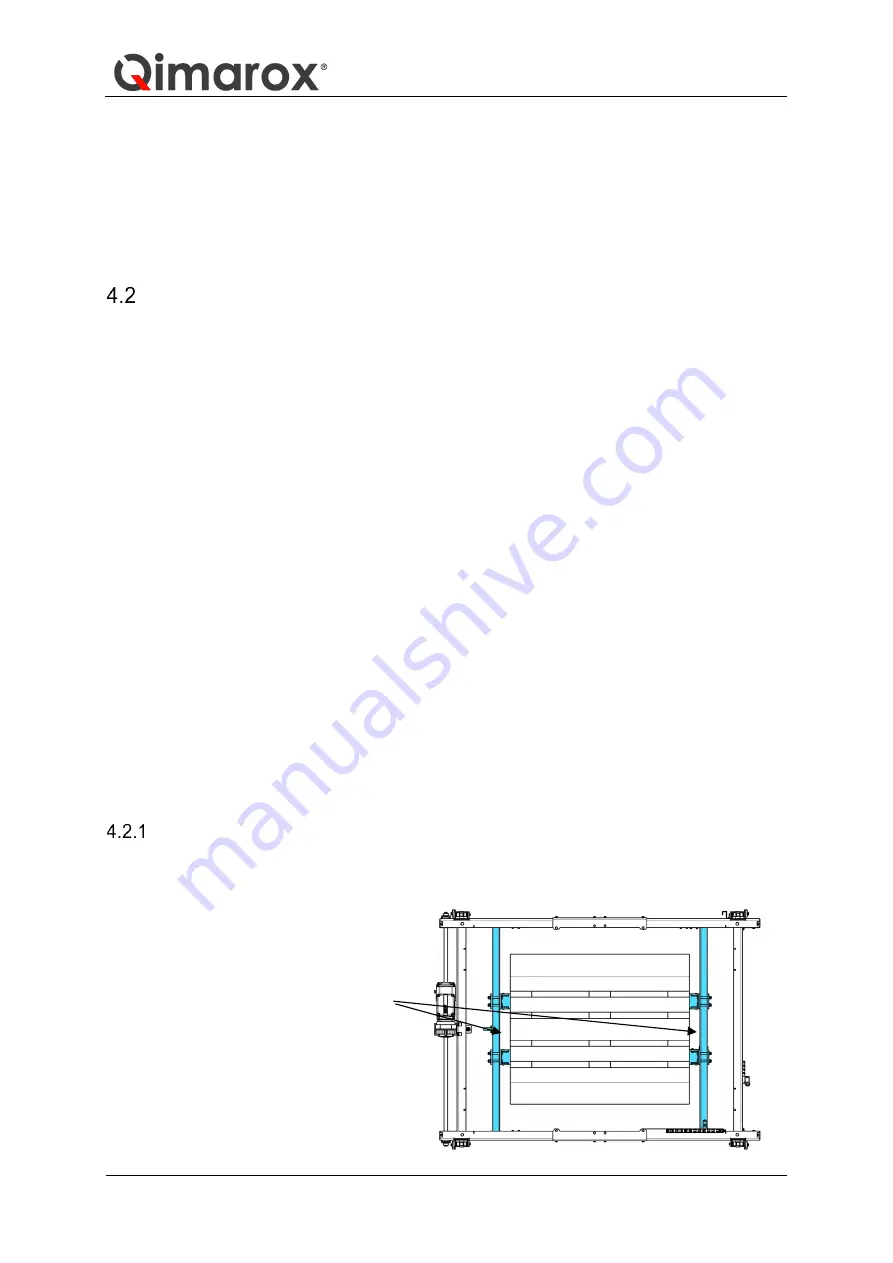

The pallet stacker module consists of the following parts:

A. Main frame

B. Pallet clamps

C. Covers

D. Sliding plates

E. Timing belt and pulleys

F. Gearmotor

Working principle

The pallet stacker is designed to stack loaded pallets on top of each other. These pallet must

be fed into the machine by a conveyor (not part of the machine). For both of the variants the

machine functions according the following steps:

1. Start - The carrier is in the middle vertical position of the Prorunner mk10 so the pallet

can enter the machine. The pallet clamps are in rest position (opened, reference

position).

2. The first loaded pallet enters the machine.

3. The first pallet has fully entered the machine and is positioned correctly on the

conveyor.

4. The carrier lowers to the bottom position.

5. The forks are inserted into the pallet until they are fully inserted. See section 3.3.8.

6. The pallet is raised it to the middle position.

7. The second pallet can enters the machine.

8. The second pallet is positioned correctly on the conveyor

9. The first pallet is lowered on top of the second pallet.

10. When the pallets are correctly stacked on top of each other, the pallet clamps move to

their rest position (opened, reference position)

11. The pallet stacker moves to the top position of the Prorunner mk10 to make way for

the stacked pallets.

12. The stacked pallets now moves out of the machine on the conveyor.

13. The carriers lowers to the middle vertical position

The vertical position of the carrier is determined by the proximity sensors of the Prorunner

mk10. For the positioning of the carrier refer to the manual UM Prorunner mk10, section 4.2.

Sliding of the pallet clamps

To clamp the pallets and lift them, the pallet stacker uses pallet clamps that slide through the

main frame of the pallet stacker.

Pallet clamps