5

The various parameters are arranged in different groups, called PAGES, depending upon the functions they represent. Each

group is assigned a unique numeric value, called PAGE NUMBER, for its access.

The parameters are always presented in a fixed format: The Lower Readout displays the parameter prompt (Identification

Name) and the Upper Readout displays the set value. The parameters appear in the same sequence as listed in their

respective sections.

SET-UP MODE

The Set-up Mode allows the user to view and modify the parameter values. Follow the steps below for setting the parameter

values:

1. Press and release

PAGE key. The Lower Readout shows PAGE and the Upper Readout shows page number 0. Refer

Figure 3.1.

2. Use UP / DOWN keys to set the desired PAGE NUMBER.

3. Press and release ENTER key. The Lower Readout shows the prompt for the first parameter listed in the set PAGE and the

Upper Readout shows its current value. If the entered PAGE NUMBER is invalid (contains no parameter list or any

associated function), the

reverts to the MAIN Display Mode.

indicator

4. Press and release the ENTER key until the prompt for the required parameter appears on the Lower Readout. (The last

parameter in the list rolls back to the first parameter).

5. Use UP / DOWN keys to adjust the parameter value. (The display flashes if UP key is pressed after reaching the maximum

value or DOWN key is pressed after reaching the minimum value).

6. Press and release the ENTER key. The new value gets stored in the indicator’s non-volatile memory and the next

parameter in the list is displayed.

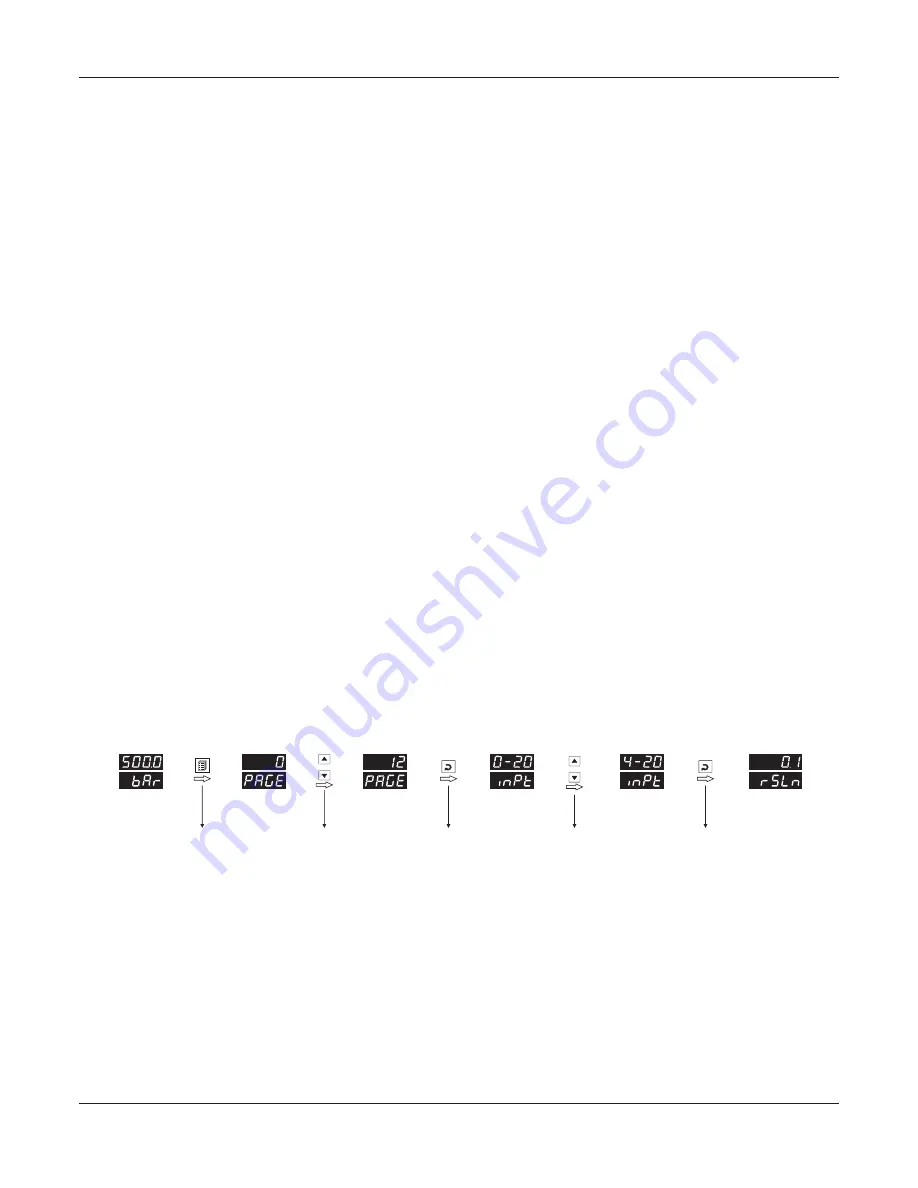

The Figure 3.1 illustrates the example of altering the value for the parameter ‘Input type’.

SET-UP MODE : ACCESS AND OPERATION

Figure 3.1

Press

PAGE

key to enter

Set-up mode

Press

ENTER

key to open

the Page

Use

UP/DOWN

keys to set the

Page Number

MAIN

Display

Mode

Default Page

Page Number

or

Use

UP/DOWN

keys to change

the value

Press

ENTER

key

to store the value &

move to next parameter

First Parameter

on PAGE-12

Next Parameter

on PAGE-12

or

New Parameter

value

Notes

1. Each page contains a fixed list of parameters that are presented in a pre-determined sequence. Note however that availability of a few

parameters, called Conditional Parameters, depend upon the settings for some other parameters. For example, the parameter ‘Alarm

Setpoint’ is available if corresponding ‘Alarm type’ is set to other than ‘none’.

2. To exit the set-up mode and return to the MAIN Display Mode, press and release PAGE key.

3. If no key is pressed for approximately 30 seconds, the set-up mode times out and reverts to the MAIN

Display Mode.

User Manual

neuro 100

Section 3