Chapter 9 Specification

ADSD-S-S

91

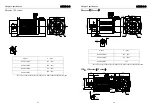

9-6 Drive motor adapter table

Motor Parameter

Servo drive model

Motor Code

[*]

Motor Model

Rated Torque

(N.m)

Rated Speed

(rpm)

Rated Power

(kW)

15B

20B

30B

S60-006M30

0.6

3000

0.2

●

S60-013M30

1.3

3000

0.4

●

S60-019M30

1.9

3000

0.6

●

S80-013M30

1.3

3000

0.4

●

S80-024M30

2.4

3000

0.75

●

S80-035M20

3.5

2000

0.73

●

S80-040M25

4

2500

1.0

●

●

●

S90-024M30

2.4

3000

0.75

●

●

●

S90-035M20

3.5

2000

0.73

●

●

●

S90-040M25

4

2500

1.0

●

●

●

B101

S110-020M30

2

3000

0.6

●

B101

S110-040M20

4

2000

0.8

●

●

B102

S110-040M30

4

3000

1.2

●

●

B103

S110-050M30

5

3000

1.5

●

●

B102

S110-060M20

6

2000

1.2

●

●

B104

S110-060M30

6

3000

1.6

●

●

B301

S130-040M25

4

2500

1.0

●

●

B303

S130-050M25

5

2500

1.3

●

●

B304

S130-060M25

6

2500

1.5

●

●

B306

S130-077M25

7.7

2500

2.0

●

B302

S130-100M10

10

1000

1.0

●

●

B308

S130-100M15

10

1500

1.5

●

●

B309

S130-100M25

10

2500

2.6

●

B310

S130-150M15

15

1500

2.3

●

● indicated can match use

*:Motor code to set the drive parameter L002。

Chapter 10 Application examples

ADSD-S-S

92

Chapter 10 Application examples

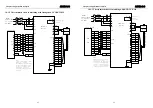

10-1 ADSD-S drive and numerical control system

10-1-1 The electrical schematic diagram with HNC-21T

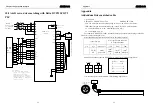

RB

RB1

W

PE

Servo

motor

Encoder

Red

White

Black

Green

Built braking

resistor

Tw

is

te

d-

sh

ie

ld

w

ir

e

AC220/

230V 1-phase

or 3-phase

50/60Hz

CN2

5

A+

10

A-

4

B+

9

B-

3

Z+

8

Z-

2

U+

7

U-

1

1

V+

6

V-

12

W+

11

W-

13

+5V

14

GND

15

FE

CN1

Metallic shell

Note:

1.Each digital signal output

interface is software

programmable .The chart shows

is the factory default value

setting it can meet general

application , users can

according to what they need

to modify.

13

PULS+

4

PULS-

14

SIGN+

5

SIGN-

2

DO2

12

DOCOM

1

DI1

26

CZ

1

CP+

9

CP-

2

DIR+

10

DIR-

5

DALM

11

0V

7

EN

4

+24

3

PC

XS30/31/32

GSK-

218M

FG

Metallic

shell

ALM

SON

Metallic

shell

22

COM+

T

S

R

MCCB

ADSD-S-S

Control

MC

L1

L2

V

U