Wiring

Operating Manual PMCprotego S2-2(-C)

1002529-EN-04

51

6.3

Shielding

For immunity reasons, the signal lines for the digital inputs and outputs must be shielded:

}

All shielded cables are to be attached at both ends to the shield terminals provided.

}

Use cables with a braided shield, with a minimum coverage of 80 %.

}

Any interruptions to the shielding e.g. at terminals, should be bridged at low impedance

over a wide area.

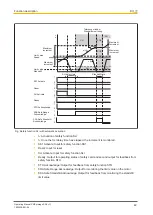

The shields for the digital inputs and outputs should be connected to the front of the servo

amplifier, as shown in the diagram below.

(1)

(2)

(3)

Remove the outer cable sheath and the

braided shield to the required wire length.

Secure the wires with a cable tie.

Remove the outer cable sheath to a length

of approx. 30 mm. Be careful not to damage

the braided shield.

Strip all the wires and fit end ferrules.

Use the cable ties to attach the cable to the

shielding plate on the side (1) or bottom (2)

of the servo amplifier. Press the cable's

braided shield firmly against the shielding

plate on the servo amplifier using a cable

tie.

Alternatively you can use the shielded con-

nection terminals (3) (available as an ac-

cessory). These hook into the bottom

shielding plate and guarantee optimum con-

tact between the shield and the shielding

plate.