6

Process data channel

The process data channel is used for real-time communication. This channel can effectively be

divided into two telegram portions:

PZD1:

Control word (STW) /Status word (ZSW) – instrument control

The control word and the status word are used to control the instrument and

monitor the status of the instrument.

PZD2-6:

Setpoint / actual values depending on the operating mode.

Setpoints and actual values such as position, velocity and current are exchanged

in this section.

The availability of a process data channel is determined in the PROFIDRIVE drive profile. The sig-

nificance of the process data is defined according to the operating mode. The process data that are

used are determined in such a way that the real-time capability of this channel is optimally used. A

central role is played by the parameter “Selector for operating modes” (see Chapter 5.2.2.3), that is

used to choose between individual operating modes.

In the following, the instrument control is described first, and then the significance and functioning of

the operating modes.

6.1

Instrument control

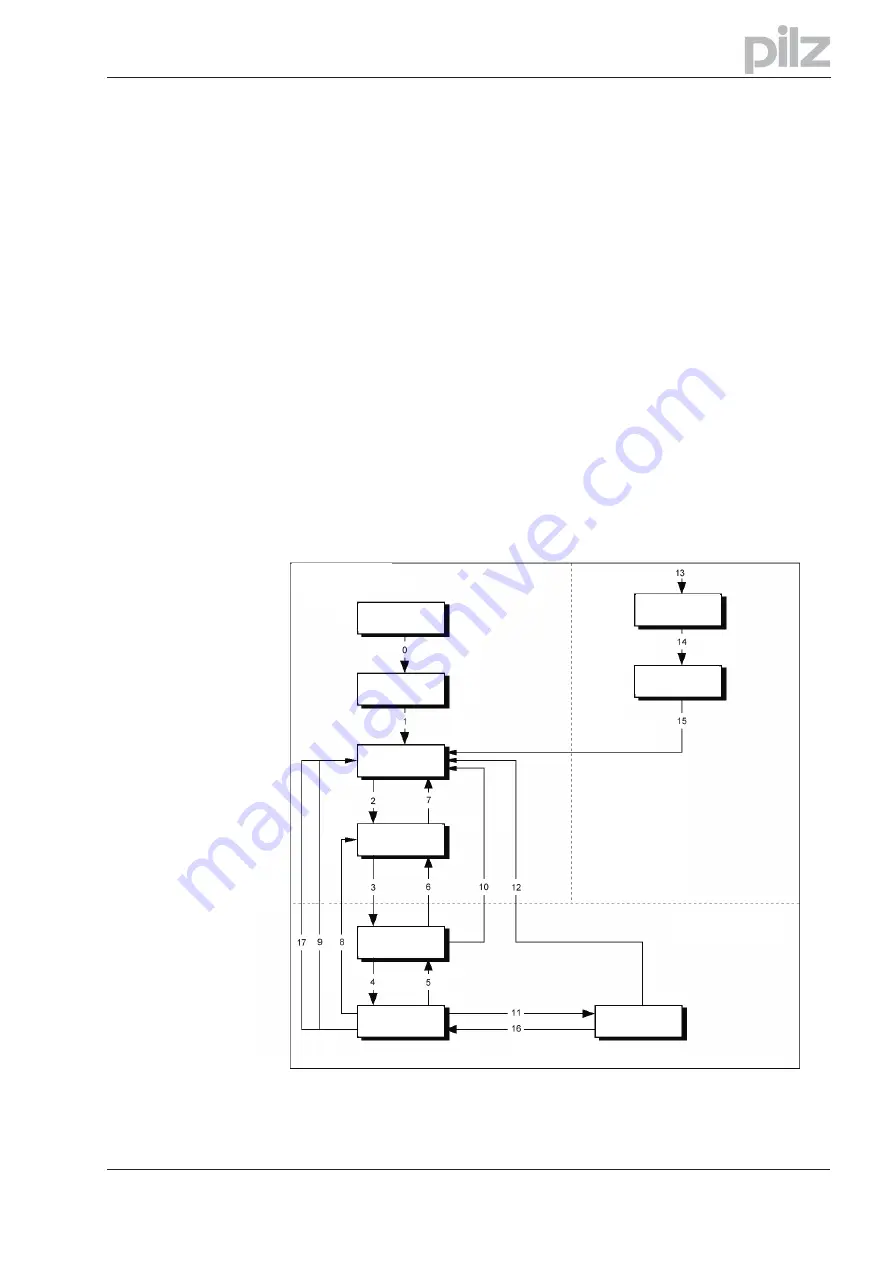

The control of the instrument is described with the aid of a status machine. The status machine is

defined in the drive profile by a flow diagram for all operating modes. The following diagram shows

the possible instrument states for the PMCtendo DD4.

User manual PROFIBUS DP PMCtendo DD4

Page 35

6 Process data channel

Output stage not

switched on

Error

Output stage

switched on

Start

Fast stop

Error

Eror response

active

Operation

enabled

Ready for

operation

Ready for

switch-on

Switch-on

inhibited

Not ready to

switch-on