OPERATING AND INSTALLATION INSTRUCTIONS LG 250 A

PAGE 49

U

S

ER

G

ENER

A

L

S

P

EC

IA

LIS

T

P

ER

S

O

NNEL

Changes reserved

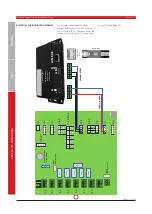

When connecting an external reheater

battery, the supply air temperature sensor

T4 installed in the ventilation unit must

be connected to input T5 (outdoor air

temperature).

The external supply air sensor (available

as an optional accessory), 5 m in length, is

connected to input T5 and installed in the

air duct after the heater battery. The user

must switch to the "Re-heater battery"

parameter in the operating software.

If a temperature sensor is not connected

to input T5, a fault message is output.

Where the reheater battery is controlled

using external temperature control, the

reheater battery parameter in the operat-

ing software must be set to "None".

Connection for an electric reheater battery

16. Maintenance and cleaning

Always pull the mains plug or

fully isolate the ventilation unit

from the mains when carrying

out cleaning or maintenance work on the

ventilation unit!

Other unit parts and components e.g. geo-

thermal heat exchanger, pre- and reheat-

er battery, sound absorbers etc. must be

serviced and cleaned in accordance with

the regulations and instructions. When

opening or unscrewing the front cover or

covers, always proceed with extreme care,

with due attention to safety and risks.

If possible, use a vacuum cleaner to

remove dirt and dust. Applying force or

using compressed air for cleaning may

damage components and surfaces.

Never use aggressive or solvent-contain-

ing cleaning agents.

The electrical components must not be

exposed to moisture or wet conditions.

The

Safety

information under

Section 4

- and in particular the

point on electrical

connections (Page 9) -

must be observed

when performing any electrical work.

SAFETY INSTRUCTIONS

Only specialists are allowed to

carry out the work specifi ed

below on the ventilation unit. Any

defects detected during servicing must

be remedied immediately to ensure safe

operation of the unit.

Only original spare parts may be used for

repairs and replacements.

MAINTENANCE INSTRUCTIONS FOR SPE-

CIALIST COMPANIES

Attention:

Bypass fl aps do not

move or drive manually.

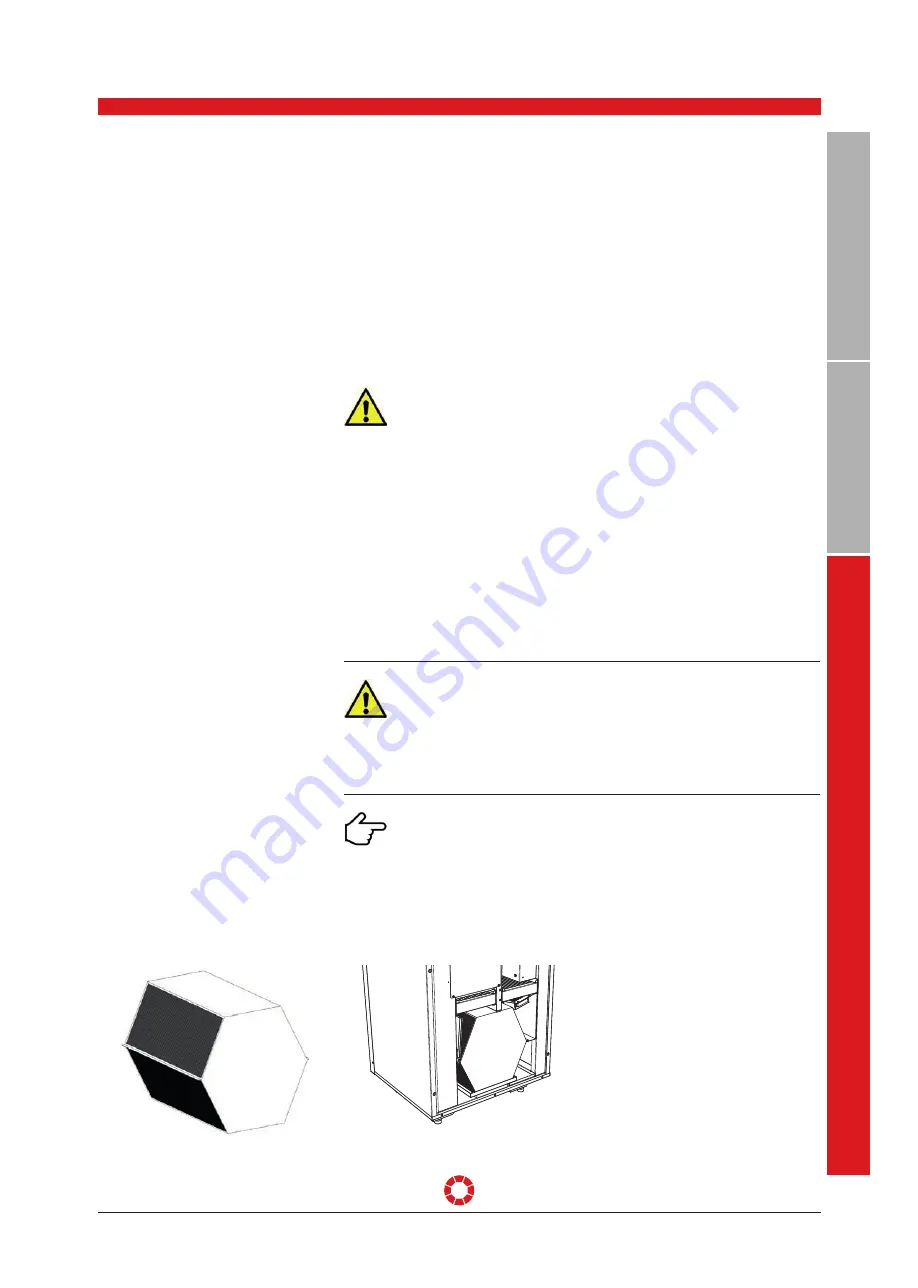

Annual cleaning is recommended at the

least, depending on the degree of soiling

of the heat exchanger.

The heat exchanger must be carefully

removed from the unit for maintenance.

The heat exchanger can be cleaned by

rinsing with warm water (maximum

50 °C) and normal detergents, and fi nally

rinsing with warm water. Never blast the

exchanger with compressed air. This can

destroy the heat exchanger!

Before installing the exchanger in the

unit, the guide rails on the heat exchanger

must be greased lightly to ensure easy

and smooth insertion.

HEAT EXCHANGER WITH BYPASS FLAP

A

1

2

3

C

E

1

D

2

3

B

7

A

E

IN

B

A

U

V

O

R

S

C

H

L

A

G

C

4

4

5

6

7

E

D

5

6

B

Benennung:

Datum:

Gezeichnet:

Kunde:

Blatt Nr.

Dateiname:

Maßstab:

DIESER PLANUNGSVORSCHLAG IST NUR IN VERBINDUNG MIT UNSEREN VORBEMERKUNGEN GÜLTIG!

BEHÖRDENAUFLAGEN SIND BAUSEITIG ABZUKLÄREN UND UNBEDINGT EINZUHALTEN!

NATURMASZE UND HÖHENKOTEN SIND ZU ÜBERPRÜFEN!

UNSTIMMIGKEITEN SIND MIT DEM PLANVERFASSER ABZUKLÄREN!

ALLE MASZE SIND VOR DER AUSFÜHRUNG VOM KUNDEN ZU PRÜFEN!

Geprüft:

Diese Zeichnung stellt

nach

den Urh. Ges § 24 unser geistiges Eigentum

dar und darf ohne unsere ausdrückliche Zustimmung weder Konkurrenzfirmen,

noch dritten Personen weitergegeben werden. Die unbefugte bzw. bestimmungswidrige

Verwendung dieser Unterlagen ist nicht gestattet und wird gerichtlich verfolgt.

08LG250-A-L-V LG250 Baugruppe

Gerät L

Baugruppe.idw

23.01.2017

wroth

Prüfer:

1 von 1

1 : 50

Freimaßtoleranz nach DIN ISO 2768-mH

Zeichnungsstatus: Freigegeben

Revision:

-

Gespeichert: 02.02.2017 14:05:13

Bauvorhaben:

Gewicht:

62,444 kg

Auftragsnummer:

J. Pichler Gesellschaft m.b.H

9021 Klagenfurt, Karlweg 5, Postfach 32

T +43 (0)46332769, F +43 (0)463 37548

[email protected], www.pichlerluft.at

wroth

30.11.2016

Zeichnungsnummer:

Artikelnummer.

08LG250-A-L-V