OPERATING AND INSTALLATION INSTRUCTIONS LG 250 A

PAGE 43

U

S

ER

G

ENER

A

L

S

P

EC

IA

LIS

T

P

ER

S

O

NNEL

Changes reserved

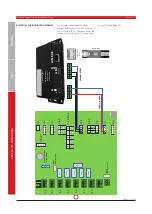

15. Electrical connection

PROCEDURE

1. Open the unit

When opening the ventilation unit to per-

form electrical connections, the wing nuts

will need to be released and the access

doors opened.

2. Controller circuit board

The control circuit board is located on the

left upper half of the unit. The protective

sheeting must be removed to access to

the terminal slots.

Attention!:

The protective sheeting is con-

nected with the unit’s earth by means of a

flush plug. The plug must be disconnected

before finally removing the protective

sheeting.

3. Cable feed-throughs

Connection cables must be fed through

the cable glad on the top of the ventilation

unit in order to connect the cables for the

relevant control unit as well as optional

system components such as external

reheating or external sensors.

4. Connecting the control unit to the

control panel

The control system consists of a control

panel and a control unit. The control panel

is connected to the control unit using a

bus connection. The control panel can

communicate internal statuses and op-

erating and fault messages to the control

unit via this line connection.

A screened cable Y(ST) J-Y(ST)Y2x2x0.8 is

required to establish the connection.

Cable length must not exceed 100 m.

The screening must be connected to the

ventilation unit’s PE protective earthing.

The connecting cable is included in the

scope of supply.

The connection to the control circuit board

and “MINI” operating unit is achieved with

a socket, and with a threaded connection

for the “TOUCH” operating unit.

• Warning: hazardous electrical

voltage!

• Disregarding the hazard may

result in death, injury or mate-

rial damage.

• Before carrying out any work on live

parts, the unit must always be dis-

connected completely from the power

supply (all poles) and secured against

being switched back on!

Electrical connection and work on electri-

cal components may only be carried out

by authorised electricians only.

The relevant national and local regula-

tions and standards must be complied

with during assembly and electrical

installation.

The LG 250 A compact ventilation unit is

designed for a 230 V/50 Hz power supply.

The unit is not designed for connection to

three-phase supply with 400 V/50 Hz.

The safety information under Item 4 -

and, in particular, the point on electrical

connections – must be observed when

performing any electrical work.

• Electrics must be connected in accord-

ance with the associated wiring plan.

(see page 45)!

• The cable cross-sections indicated are

minimum cross-sections for copper

lines and do not take cable length or site

conditions into account.

• Cable type, cable cross-section and lay-

ing must be determined by an author-

ised electrician!

• Low-voltage cables must be laid sepa-

rately from mains cables; alternatively,

screened cables must be used!

• The inlet fuse on the power supply line

must be an isolation type!

• A separate cable inlet must be used for

each cable!

• Unused cable inlets must be hermetical-

ly sealed!

• All cable entries must be strain-relieved!

• Potential equalisation must be put in

place between the unit and the air duct

system!

• All safety measures must be tested

following electrical connection! (Earth

resistance etc.)

• In order to prevent triggering inappro-

priate earth-leakage circuit breakers, it

is expressly recommended that pulsed

or all-current-sensitive circuit breakers

(Type A or B) with delayed triggering are

used.