OPERATING AND INSTALLATION INSTRUCTIONS LG 250 A

PAGE 39

U

S

ER

G

ENER

A

L

S

P

EC

IA

LIS

T

P

ER

S

O

NNEL

Changes reserved

The LG 250 A compact ventilation unit

must be installed in accordance with the

general and locally applicable safety and

installation regulations and as per the

specifications in this Manual. Mounting

and installation work may be performed

by authorised specialist personnel only.

The ventilation unit may only be installed

in a frost-free room, e.g. in a cellar or

loft, with ambient temperatures ranging

b5°C to +40°C. Accumulating

condensate water must be discharged,

frost-free and safely, via a gradient and

using effective siphoning to block odours.

The unit's installation position must allow

sufficient space for air ducts, electrical

connections, condensate drain connection

and maintenance and inspection.

Leave at least 1 m free space in front

of the unit to allow for operation and

servicing.

The ventilation unit must be set up on

an even and sufficiently firm installation

surface. The ventilation unit can also be

secured to a solid wall using the wall

assembly bracket included in the scope

of delivery. Care must be taken to ensure

the appropriate design of the (Static)

load-bearing components when doing so.

The following connection facilities must

be available in the installation area:

• Air duct connections for supply, extract,

outdoor and exhaust air

• Electrical mains connection 230 V/

50 Hz, 16 A fuse

• Condensate drain line with eff ective

odour trap (siphon)

All on-site work (drainage, floor structure

etc.) must be completed before installing

the ventilation unit. The ventilation unit

will be firmly in position once the air

ducts have been connected and cannot be

moved.

The outdoor air and exhaust air ducts, e.g.

between the ventilation unit and the roof

feed-through, must be sufficiently insu-

lated for energy reasons and to prevent

condensate formation.

Condensate must not be allowed to form

on the air ducts and roofing. Any lines

running outdoor the thermally insulated

building shell must be adequately insulat-

ed in cold areas.

To ensure proper and functional operation

of the unit, suitable thermal and sound

insulation and installation materials must

be provided as per the planning documen-

tation and technical data, such as sound

absorbers of adequate size, supply air and

extract air valves, overflow openings etc.

All equipment connectors should in

principle be fitted with sound absorbers

to ensure appropriate acoustic damping in

the living area.

Air duct feed-throughs through walls or

ceilings must be isolated against structur-

al vibrations.

To protect the unit from coarse soling

such as foliage, leaves or insects, a fine

wire mesh grating must be provided as a

pre-filter directly at the central inlet point

for outdoor air. The protective grating

must be checked and cleaned at regular

intervals, if necessary, especially in spring

and autumn.

Inspection openings should be provided in

the air duct system to facilitate cleaning

as well as maintenance of the unit.

14. Installation

PREREQUISITES FOR UNIT INSTALLA-

TION

1

2

3

4

3

1

4

2

1

2

3

4

3

1

4

2

544

484

672

332

92

77

8

633

610

16

16

87

0

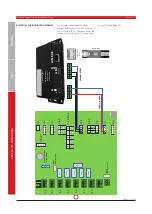

1 Zu

luft ø 160 mm

2 Abluft

ø 160 mm

3 Außenluft

ø 160 mm

4 Fortluft

ø 160 mm

5 Gegenstromwärmetauscher

6 Abluftventilator

7 Zuluftventilator

8 Steuerung

9 Bypassklappe

10 Abluftfilter G4

11 Außenluftfilter F7

12 Kondensatwanne

13 Kabeleinführung 4 x M16 / 1 x M12

14 PTC-Elektrovorheizregister (optional)

15 Höhenverstellbare Füße

16 Kondensatstutzen

Abbildung:

LG 250 A-L (linke Ausführung)

Aufbauskizze (Stand- oder Wandmontage, linke Ausführung)