19

9.

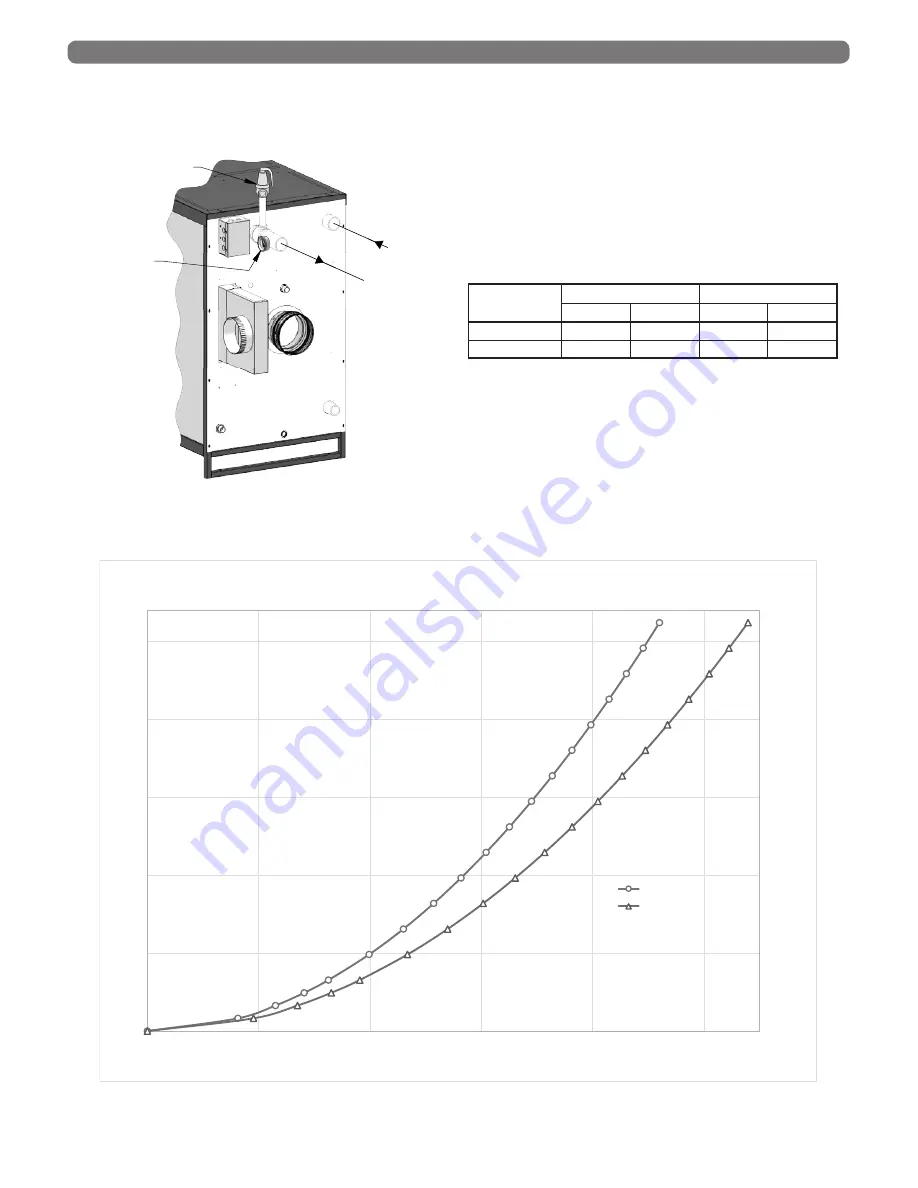

Circulator

: The boiler circulator is to be sized to

overcome the pressure drop of the system while

providing the flow required by the boiler.

a. If the boiler is piped in a secondary loop of a

primary/secondary heating system, the circulator

will need only to overcome the resistance of the

boiler and any fittings in that loop.

b. The circulator should be sized based on gross

output of the boiler. Table 4.4 shows the Boiler

Output as reported to the Hydronics Institute

Section of AHRI.

c. The required flow is calculated based on the design

temperature difference from the return to the

supply of the boiler. For a PFC-625 with a design

temperature difference of 20°F the calculation is as

follows:

Output 612,000

Required Flow =

________

=

_________

= 61.2 GPM

D

T

x 500

20 x 500

d. The boiler pressure drop for various flow rates

can be determined using Figure 4.3,

P

ure

F

ire

®

Circulator Sizing Graph below.

WATER PIPING & CONTROLS

Figure 4.3:

Series PFC

TM

C

irculator Sizing Graph (General Pump – Primary/Secondary)

0

5

10

15

20

0

100

200

300

400

500

600

700

800

0

5

10

15

20

25

0

20

40

60

80

100

Flow Rate [m

3

/hr]

Pr

essur

e

Dr

op

[mb

ar

]

Pr

essur

e

Dr

op

[F

ee

t o

f Wate

r]

Flow Rate [GPM]

PFC-625

PFC-750

Figure 4.2: Relief Valve and Pressure/Temperature

Gauge Installation

SYSTEM

SUPPLY

SYSTEM

RETURN

PRESSURE/

TEMERATURE

GAUGE

SAFETY RELIEF VALVE

(PIPE TO WITHIN

12 INCHES

OF THE FLOOR TO

PREVENT INJURY)

Table 4.5: Boiler Input and Output

P

ure

F

ire

®

Model

Boiler Input

Boiler Output

Btu/hr

kW

Btu/hr

kW

PFC-625

625,000

183.2

612,000

179.4

PFC-750

750,000

219.8

735,000

215.4