Scanner Installation

Installing the Scanner

2-7

With circuit power on and all OpScan

i

NSIGHT 70 system components

unplugged, the voltage between the circuit neutral conductor and the isolated

ground conductor must be less than 0.6 VAC.

Site Power Wiring Recommendations

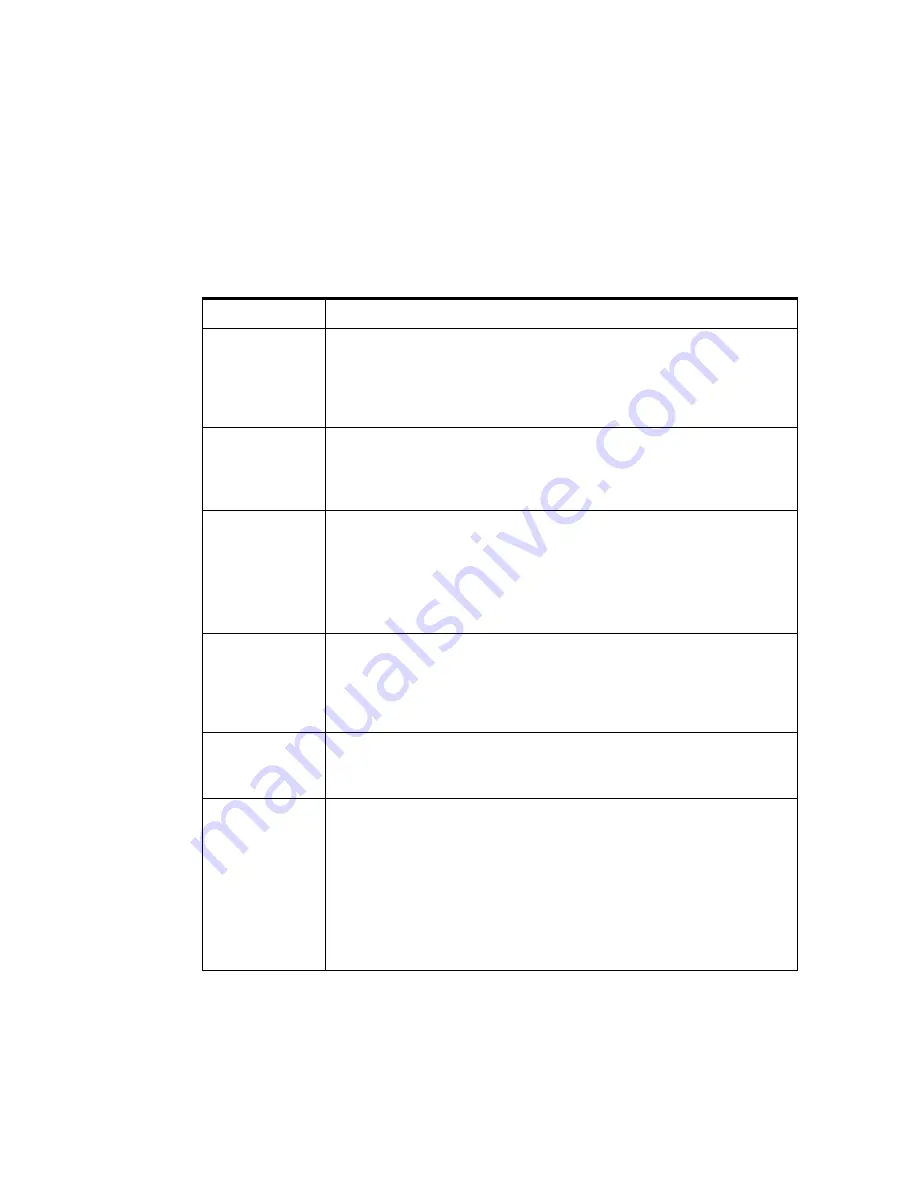

Table 2-2 describes the conditions for power wiring at a scanner site.

Table 2-2

Power Wiring at a Scanner Site

Condition

Description

Dedicated

Feeder

Run a separate dedicated feeder from the building main power panel to the

branch power panel serving the OpScan

i

NSIGHT 70 system. The cabling

should be of sufficient diameter to produce no less than 110V at the outlet

when the scanner is connected and powered on. This feeder should be a

minimum of 30 amp service to allow for future growth of the system.

Dedicated

Isolated/

Insulated

Ground

An isolated/dedicated ground is required. Run this ground conductor as an

uninterrupted circuit from the power panel to the OpScan

i

NSIGHT 70

system branch panel. The gauge of this conductor must be at least as large as

that of the AC circuit conductors in all stages of the circuit.

Panel Branch

Circuits

All branch circuits leaving the OpScan

i

NSIGHT 70 branch power panel

should be at least 10 AWG copper wire. There should be no circuits from

this power panel serving devices that are not part of the scanner system.

One branch circuit from this power panel should be dedicated at the scanner

(this circuit will also service the computer and monitor), and there should be

at least one additional dedicated circuit for each additional scanner.

Additional Utility

Convenience

Connectors

Provide additional convenience outlets in the vicinity of the OpScan

i

NSIGHT 70

scanner. Connect these outlets (may be used for vacuums,

paper joggers, and other electrical devices) to a branch panel other than the

scanner branch panel to provide maximum noise isolation for the OpScan

i

NSIGHT 70 system components.

Scanner

Electrical

Connections

Dedicate one 15 amp (120 VAC) or 7.5 amp (220 VAC) circuit to each

OpScan

i

NSIGHT 70 scanner at the site. All may be served from the same

branch panel, provided its rated capacity is not exceeded.

Electrical

Outlets

All 120V outlets for the OpScan

i

NSIGHT 70 scanner should be Hubble

IG-5362 or equivalent (NEMA 5-20R). All 240V outlets should be Hubble

IG2410A or equivalent. Outlets for the peripheral equipment should be of

the type and rating specified in the hardware reference manuals for the

equipment.

The quantity of outlets that must be provided for the peripheral equipment

varies according to system configuration. (See Panel Branch Circuits above.)

Outlets should be located within 6 feet (2 meters) of the working location of

the equipment.

Summary of Contents for OpScan iNSIGHT 70

Page 1: ...Installation Guide for the OpScan iNSIGHT 70 Scanner...

Page 2: ......

Page 5: ...iii Revision Log 203 737 002 Tab Date Description 5 05 Manual Released...

Page 6: ...iv Installation Guide for the OpScan iNSIGHT 70 Scanner...

Page 16: ...Scanner Overview Customer Support 1 6 Installation Guide for the OpScan iNSIGHT 70 Scanner...

Page 47: ......

Page 48: ...203 737 002...