© Paul Wärmerückgewinnung GmbH • August-Horch-Straße 7 • 08141 Reinsdorf • Deutschland

Tel: +49(0)375-303505-0 • Fax: +49(0)375-303505-55 • E-Mail: [email protected] • Internet: www.paul-lueftung.de

Operating data:

thermos 200 DC

thermos 300 DC

Power input:

11 to 64 W

11 to 145 W

Volumetric flow ranges:

50 to 250 m³/h

200 m³/h at 100 Pa

50 to 400 m³/h

380 m³/h at 100 Pa

Heat recovery rates:

1)

results may vary according to the

test methods used, e.g. whether

measured with or without

condensation, or whether on the

exhaust or supply air side

2)

best efficiencies in the German

market today

approx.. 97... 99 %

1)

acc. to DIBT: measured by VEW Energie AG Dortmund – supply air side)

92 %

1)2)

(effective: measured by Passivhaus Institute Darmstadt – exhaust air side)

Sound pressure level:

(3m distance, to DIN 45635

Part 1)

Vent. step 58%

Vent. step 100%

28 dB(A)

34 dB(A)

35 dB(A)

42 dB(A)

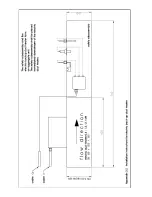

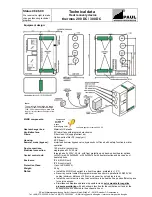

Kennlinie:

Important!

Characteristics may be different due to allowable tolerances (e.g. acc. to manufacturer: – fans 10%, transformers 5% admissible).

Operation: Operating

element (control unit):

Automatic control

Standard functions

•

8 independent time programs can be defined and assigned to any

day of the week

•

motorised summer bypass valve

•

manual stop in standby mode with limited power input below 2 W

•

manual adjustment of ventilation steps (off, minimum, normal,

maximum)

•

programmer can be installed in any place in the house

•

ventilation steps programmable in 1% increments (30-100% of

maximum fan power)

•

adjustable balance between supply and extract air fans

•

filter monitor for change interval

freeze protection for downstream hot water duct heater

Options

(with extra price for accessories)

•

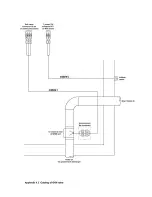

Control of an electric valve at the ground to air heat exchanger (either

air intake through the ground to air heat exchanger or direct air

intake)

•

Control of a frost protection pre-heater (frost protection heater

prevents ice formation and thus replaces a ground to air heat

exchanger in winter)

•

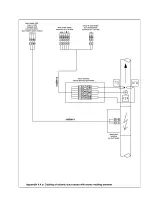

Constant flow control (permanent monitoring and balancing of the

supply and extract air flows, fireplace compliant)

•

Control of a heating circuit (e.g. heating circuit pump or electric back-

up duct heater up to 2.1 kW) – also with night reduction

•

Several boost switches can be connected to the programmer

•

The MVHR unit can be operated by several programmers (e.g. one in

the place of installation, another one in the living room). If a duct

heater is used, the room temperature is recorded at the first

programmer.

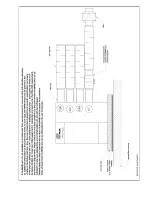

Comfort control unit

(LxWxD in mm: 158x125x32)

Cable: IYSTY 2x2x0.6, max. 15 m, by

customer

The programmer can be installed in the living

area. Further programmers (option) and boost

switches (by customer) can be connected.

Summary of Contents for thermos 200

Page 2: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......