Programming Your Application

6-14

650G AC Drive

PID - Tuning Your Drive

This section relates to the use of Application 5.

Parameters

to

: PID is used to control the response of any closed loop system. It is

used specifically in system applications involving the control of drives to provide zero steady

state error between Setpoint and Feedback, together with good transient performance.

P

roportional Gain (

)

This is used to adjust the basic response of the closed loop control system. The PI error is

multiplied by the Proportional Gain to produce an output.

I

ntegral (

)

The Integral term is used to reduce steady state error between the setpoint and feedback values

of the PI. If the integral is set to zero, then in most systems there will always be a steady state

error.

D

erivative (

)

This is used to correct for certain types of control loop instability, and therefore improve

response. It is sometimes used when heavy or large inertia rolls are being controlled. The

derivative term has an associated filter to suppress high frequency signals.

•

Functions as P, PI, PID controller

•

Single symmetric limit on output

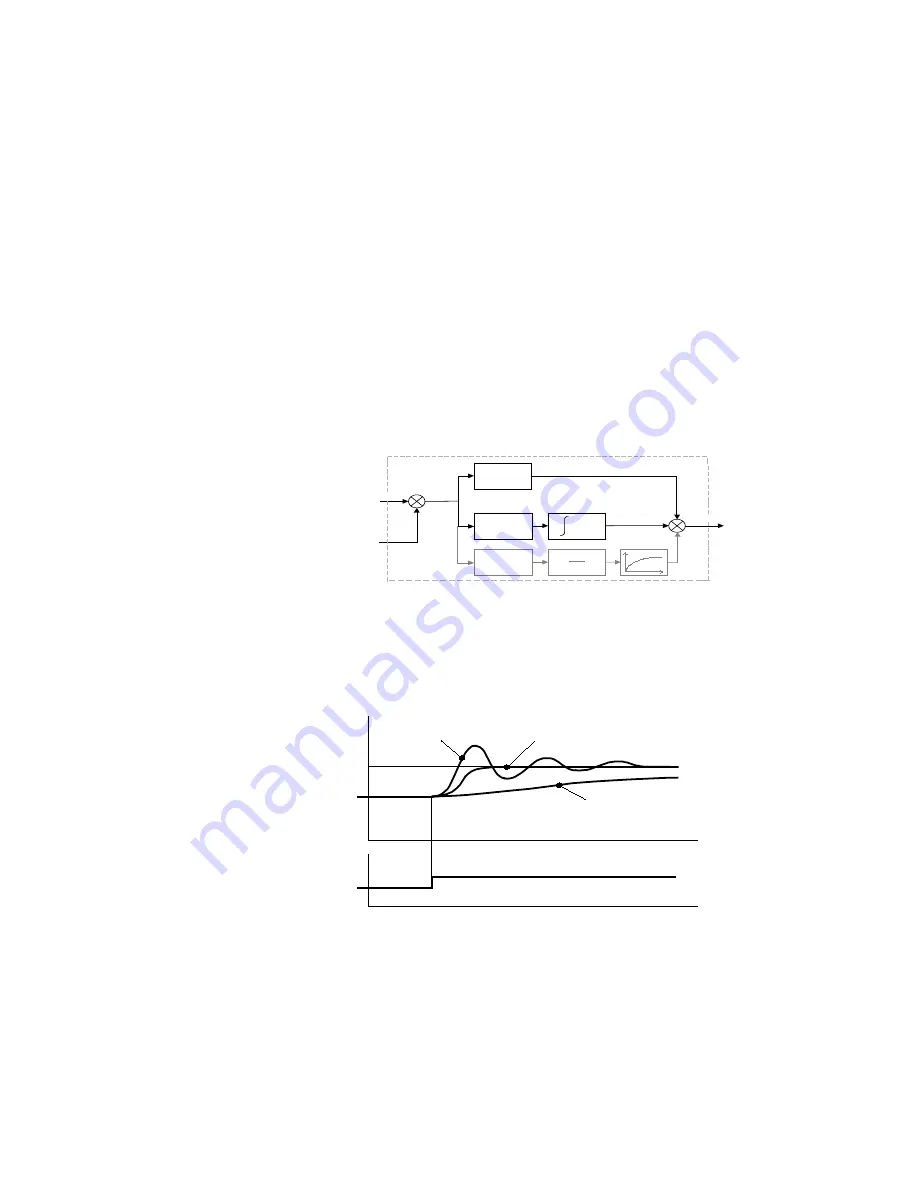

A Method for Setting-up the PI Gains

The gains should be set-up so that a critically damped response is achieved for a step change in

setpoint. An underdamped or oscillatory system can be thought of as having too much gain, and

an overdamped system has too little.

To set up the P gain, set the I gain to zero. Apply a step change in setpoint that is typical for the

System, and observe the response. Increase the gain and repeat the test until the system becomes

oscillatory. At this point, reduce the P gain until the oscillations disappear. This is the maximum

value of P gain achievable.

If a steady state error is present, i.e. the feedback never reaches the setpoint value, the I gain

needs to be increased. As before, increase the I gain and apply the step change. Monitor the

output. If the output becomes oscillatory, reduce the P gain slightly. This should reduce the

steady state error. Increasing the I gain further may reduce the time to achieve zero steady state

error.

These values of P and I can now be adjusted to provide the exact response required for this step

change.

Underdamped (oscillatory)

Critically Damped

Overdamped

OUTPUT

SETPOINT

P G a in

I G a in

d t

S e tp o in t

E r r o r

+

-

+

+

O u tp u t

F e e d b a c k

( A IN 2 )

( A IN 1 )

D G a in

d t

d

+