7

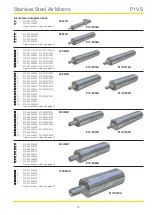

Stainless Steel Air Motors

P1V-S

All catalogue data and curves are specified at a supply pres-

sure of 6 bar (in the inlet port). This diagram shows the effect of

pressure on speed, torque, power and air consumption.

Start off on the curve at the pressure used and then look

up to the lines for power, torque, air consumption or speed.

Read off the correction factor on the Y axis for each curve and

multiply this by the specified catalogue data in the table or

data read from the torque and power graphs.

Example:

at 4 bar supply pressure, the power is only

0,55 x power at 6 bar supply pressure.

This example shows how rapidly the power rating of a motor

decreases as the supply pressure is reduced. Therefore, it is

critical to ensure that the proper pressure is supplied at the

inlet port of the motor.

Direction of motor rotation

The most common way to reduce the speed of a motor is to

install a flow control in the air inlet. When the motor is used

in applications where it must reverse and it is necessary to

restrict the speed in both directions, flow controls with integral

non-return function should be used in both directions. Restric-

tion may also be applied to the main outlet which will control

the speed in both directions.

Inlet throttling

If the inlet air is restricted, the air supply is restricted and the

free speed of the motor falls, but there is full pressure on the

vanes at low speeds. This means full torque is available from

the motor at low speed, despite the low air flow.

Since the torque curve becomes “steeper”, this also means

that we get a lower torque at any given speed than would be

developed at full air flow.

Pressure regulation

The speed and torque can also be regulated by installing

a pressure regulator in the inlet pipe. When the motor is

constantly supplied with air at lower pressure and the motor is

braked, it develops a lower torque on the output shaft.

In brief:

Inlet throttling

gives reduced speed in one direction

but maintains torque when braked.

The torque curve becomes

steeper

.

A restriction in the main inlet

gives reduced speed in

both directions but maintains torque when braked.

The torque

curve becomes steeper

.

Pressure regulation

in the inlet cuts

torque when the motor is braked, and also reduces speed.

The

torque curve is moved parallel.

P = power

Q = air consumption

M = torque

n = speed

Speed regulation

Throttling

Supply throttling,

nonreversible motor.

Outlet throttling.

Supply throttling,

reversible motor.

Pressure regulation at

motor inlet.

Correction diagram

n = f (p)

p [bar]

Q = f (p)

M = f (p)

P = f (p)

0,4

0,3

0,5

0,6

0,7

0,8

0,9

1,0

1,1

1,2

1,3

3

4

5

6

7

Correction factor

M

M

Torque curve

change caused by

throttling.

Torque curve

change caused by

pressure change.

The direction of rotation of reversible motors is controlled by

supplying inlet L or inlet R with compressed air. Air motors can

be stopped and started continually without damage.

As the motor begins to rotate air is trapped between the

vanes and is compressed. This air is exhausted through the

exhaust port. As the rotor continues it’s rotation, trapped air is

compressed and exhausted through the residual port. If this

air is not exhausted, the motor will be braked and maximum

power will not be obtained.

Main outlet

Main outlet

Residual

outlet

Residual-

outlet

Inlet, counter

clockwise

Inlet,

clockwise

Summary of Contents for 1P1V-S020A00005

Page 66: ...66 Stainless Steel Air Motors P1V S...

Page 67: ......