44

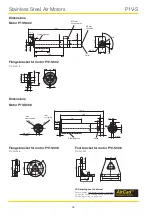

Drilling, milling and grinding motors

P1V-S

Drilling, milling and grinding motors

A large number of drilling motors, milling motors and grinding motors

have been developed using the P1V-S as the base motor in order

to make it easier to install air motors in machining applications.

These motors are all equipped with standard vanes for intermittent

lubrication-free operation, although it is recommended to use oil mist if

you are planning to operate them for extended periods.

NOTE! These motors are not made of 100% stainless steel.

Drilling motors are available with power ratings of 80, 170, 50 and

400 Watts, and several different speeds for the machining of a range

of materials. They can be fitted with collet chucks, drill chucks and

quick-release chucks. Many of them also have accessories allowing

the exhaust air to be removed.

The milling motor, with a power rating of 400 Watts, runs at a relatively

high speed, and is fitted with a collet chuck for a shaft diameter of 8

mm. It is equipped with strong bearings able to handle greater shear

forces on the spindle.

The grinding motor, with a power rating of 00 Watts, is fitted with a

collet chuck for a shaft diameter of 8 mm and runs at a relatively high

speed. It is equipped with strong bearings able to handle greater

shear forces on the spindle.

The design principle of the 90 Watt grinding motor is different from

the others. The turbine principle means that high speeds are possible

without the need for lubrication.

Feed movement in drilling, milling and

grinding motors

A slow and even feed movement is necessary in machining

applications. During drilling, the feed must not uncontrollably speed

up once the drill breaks through the material. One good way of solving

the problem is to use a pneumatic cylinder for the feed, which is able

to provide force during drilling and a rapid approach before the actual

drilling phase. Feed during the drilling phase is controlled using a

hydraulic brake cylinder (HYDROCHECK) fitted in parallel with the

pneumatic cylinder. This provides even, slow and safe feed movement,

without the risk of the uncontrolled feed described above.

Technical data:

Working pressure:

Max 7 bar

Working temperature:

-30 °C to +100 °C

Medium:

40 µm filtered oil mist

(unlubricated for grinding motor P1V-S009)

Other technical data

See table for each motor

Material specification

Drilling motors P1V-S008N, P1V-S05N/M, P1V-S040M,

milling motor P1V-S040N and grinding motor P1V-S00N

Housing

Stainless steel, X1Cr13

Shaft, collet chuck

Hardened steel (not stainless)

Shaft for drill chuck

Hardened and tempered steel

(not stainless)

Drilling motors P1V-S017N/M and

grinding motor P1V-S009N

Housing

High grade steel (not stainless)

Shaft, collet chuck

Hardened steel (not stainless)

Shaft for drill chuck

Hardened and tempered steel

(not stainless)

All

Internal parts

High grade steel (not stainless)

Accessories

Surface treated steel, plastic

aluminium

P 1 V - S

0 1 7

N

0

Q 0 0

Order key

Possible combinations

Please refer to pages 45 to 5.

Function

M

B10/B1 shaft

N

Collet chuck

Motor size

008

80 W

009

90 W

017

170 W

025

50 W

030

300 W

040

400 W

Free speed

per min

035

350

999

9990

A00

10000

H00

17000

L00

0000

Q00

4000

X00

30000

A000

100000

Air motor range

P1V-S

Drilling, milling and grinding motors

Summary of Contents for 1P1V-S020A00005

Page 66: ...66 Stainless Steel Air Motors P1V S...

Page 67: ......