BA_PH_BSB-400-900_EN_44-21.docx

33

9.7

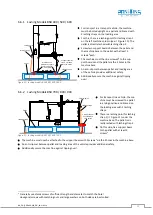

APA 2 - Saw Blade Guides

9.7.1

Structure and Components

The adjustment of the two saw blade guides is necessary

when starting up the machine as well as when changing

the bandsaw blade.

The structure is identical for the upper and lower saw

blade guide. The proven APA 2 saw blade guide consists of

the following components:

Pos. Description

Pos. Description

B

Support bolt

R

Back roller

8

H

Holder

S

Side rollers

K1

Tommy screw 1

V

Sealing plug

K2

Tommy screw 2

X

Rear clamp

L

Side bearing sleeve

Y

Front clamp

Figure 29: APA - Structure and components

9.7.2

Adjusting the Saw Blade Guides

To ensure proper functioning of the bandsaw, the two saw blade guides, each with two side rollers and a back

roller, must be correctly adjusted. The two side rollers serve to fix the saw blade laterally in the correct position.

The purpose of the back roller is to support the bandsaw blade during cutting against the force and movement

of the workpiece feed from behind.

Before adjustment, clean the guides thoroughly and remove dust, dirt and resin deposits. The procedure for

adjustment is identical for the upper and lower saw blade guides:

Figure 30: Adjusting the guides

•

Loosen the back roller with the tommy screw (

K2

) and move

it all the way back by pulling the sealing cap

8

on the back.

•

Adjust the two side rollers with the side bearing sleeves (

L

)

outwards so that a newly placed saw blade can run freely

between them.

•

Place the saw blade, tension and align it (see

9.3).

•

Loosen the tommy screw (

K1

) and adjust the complete

guide on the support bolt (

B

) by moving it so that the front

edges of the side rollers are approx. 1 - 2 mm behind the

tooth base of the saw blade (see

•

Place the back roller against the back of the saw blade so

that it is not touched when the machine is idling.

•

Only the cutting pressure during machining may cause the

saw blade to touch the back roller.

•

Adjust side rollers so that they only lightly touch the saw

blade (see

Figure 31). Please take care that the saw

blade is not pushed to the side!

•

After adjustment, tighten tommy screws (

K1

) and (

K2

).

The bandsaw blade guide must not be set too high during machining.

There is a risk of injury from flying chips and a free-running saw blade!

8

With sealing cap (not visible in picture, as attached on the back)

S

L

V

B

R

K1

H

Y

X

K2

1-2 mm

K1

L

L

K2

Rear

(hidden view)