BA_PH_BSB-400-900_EN_44-21.docx

31

9.3

Inserting and Tensioning a Bandsaw Blade

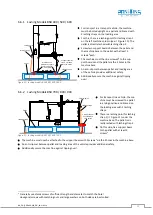

To ensure safe working without incidents, the bandsaw blade must be placed and adjusted properly. For wide

blades, at least two persons are required for this purpose.

Caution: Danger of cutting! Put on protective gloves when changing the bandsaw blade!

•

Disconnect and secure models without a main switch or turn off and lock the main switch with a padlock.

•

Unlock the two safety switches for the doors (

a

) and (

b

) according to section

The doors of the bandsaw can only be opened if the safety switches have been unlocked be-

forehand with the knurled screws (R), see section

9.2. Before the machine can be started

again, the safety switches must first be locked.

Figure 25: Overview - Inserting and tensioning the bandsaw blade

•

Open both doors (

a

) and (

b

) and the blade guard (

8

).

•

Remove chip catcher (

S

) by pulling it out.

•

Loosen the handwheel (

10

) for the band tension and remove the old bandsaw blade if necessary.

•

Place the new blade on the wheels (teeth pointing outwards) and pretension slightly via handwheel (10).

•

Reconnect the machine to the mains or (if present) switch on the main switch again.

•

Only on machines with mechanical motor brake

→

Turn brake release switch

to position “

active

”

.

•

Now check by turning manually whether the belt runs cleanly and centrally and align if necessary.

•

Set the final saw blade tension with the handwheel (

10

) and the pointer (

Z

) of the blade tension indicator.

The blade tension is indicated by the pointer (Z). The blade must be tensioned until the

pointer points to the line that corresponds to the indicated blade width.

Example 30 mm blade

→

The pointer (

Z

) must point to the line belonging to No. 30.

•

Push the chip catcher (

S

) back in and close the blade guard (

8

).

•

Close the doors again, lock the safety switch and switch off the brake release switch if necessary.

•

Switch on bandsaw blade and start test run.

10

8

a

b

S

Z