BA_PH_BSB-400-900_EN_44-21.docx

23

6.6.1

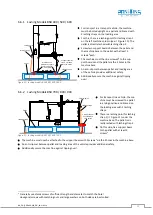

Lashing Models BSB 400 / 500 / 600

Figure 10: Lashing models BSB 400 / 500 / 600

•

For transport in a transport vehicle, the machine

must be bolted upright on a pallet and braced with

2 lashing straps on the loading area.

•

For this, there is a lashing point for lashing strap 1

on the left machine column (see

Figure 10). The

pallet is directly lashed with lashing strap 2.

•

Screw two support boards between the pallet and

the machine base to the pallet with at least 3

screws

4

each.

•

The machine must then be screwed

4

to the sup-

port boards and the pallet via the 4 holes in the

machine base.

•

An anti-slip mat between pallet and loading area

of the vehicle provides additional safety.

•

Additionally secure the machine against tipping

over!

6.6.2

Lashing Models BSB 700 / 800 / 900

Figure 11: Lashing models BSB 700 / 800 / 900

•

For transport in a vehicle, the ma-

chine must be screwed to a pallet

in a lying position and braced on

the loading area with 2 lashing

straps.

•

There is a lashing point for lashing

strap 1 (

Figure 11) under the

machine base. The pallet is di-

rectly lashed with lashing strap 2.

•

On this side, fix a support beam

to the pallet with at least 3

screws

4

.

•

The machine must now be attached to the support beam with 2 screws

4

via the 2 holes in the machine base.

•

An anti-slip mat between pallet and loading area of the vehicle provides additional safety.

•

Additionally secure the machine against tipping over!

4

Generally use sturdy screws of sufficient length and diameter to match the hole!

Hexagonal screws with matching nuts and large washers on both sides are best suited.

2 support boards

each 3 x screwed

onto the pallet

Machine base

screwed to support

boards and pallet

with 4 screws

Lashing strap 1

Pallet

Lashing strap 2

Lashing point

Pallet

Lashing strap 1

1 support beam

3 x screwed to

the pallet

Lashing strap 2

Lashing point