E-025-2-E

5

3.10.1.3 Deleting Files

It is possible to delete data files that are no longer necessary.

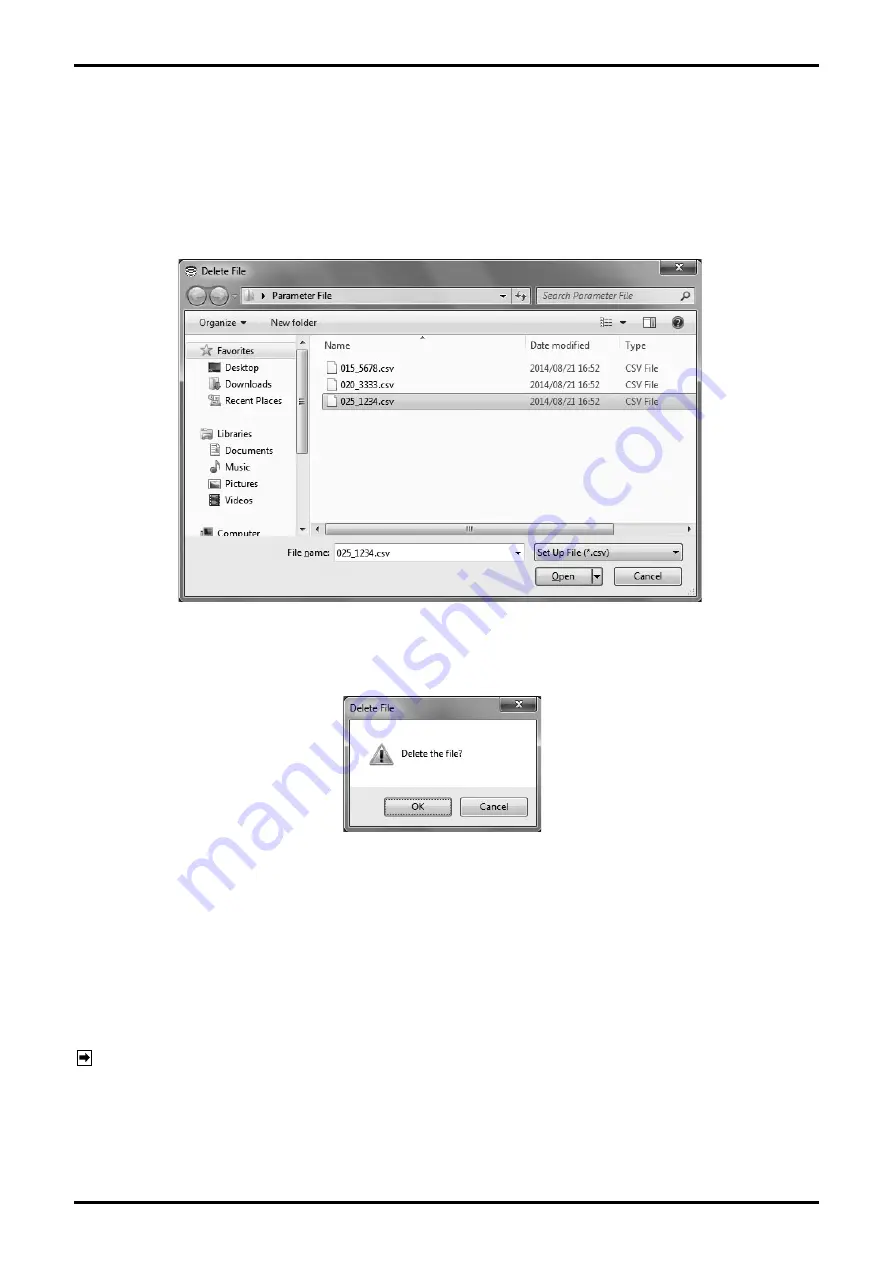

① Click "File (F)" from the menu, and select "Delete File" from the list of "Database", then the

following dialog box (Fig. 131) will be displayed. Select the disk and folder where the relevant file

is stored from the list and specify the file. Then click "Open (O)" .

Fig.131

② A message box (Fig. 132) will be displayed. Click "OK" to delete the file.

Fig.132

3.10.1.4 Downloading

This function is used to send all the parameters from a selected file to the flowmeter transmitter.

This makes it possible to use the same parameters to set up another flowmeter transmitter (to copy

settings).

However, rewritable parameters are limited to those related to the measuring condition or output.

Parameters specific to a transmitter, coefficient (Basis coef 1 to Basis coef 8) used for calculation of

the reference flow, and data related to analog output adjustment (Trim Analog) cannot be overwritten.

NOTE: Parameters not overwritten: [Basis coef1 to 8] [Calibration Zero] [Calibration Factor] [Device ID]

[Sensor Serial No.] [Final Assembly No.] [Hardware rev] [Password Option] [Setting Password]

[Polling Address] [RS485 Baudrate] [4mA adjust value] [20mA adjust value]

Before executing downloading, confirm the parameter currently set to the flowmeter and make sure

the flowmeter is the one suitable for this operation.