INSTALLATION AND STARTUP

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

7

2.2

PRODUCT MOUNTING

It is recommended to mount the unit to a solid structure (such as a concrete wall, steel column, or angle iron) where

a minimum of vibration will be transmitted to the unit. Alternately, a pole may be used along with a strap or a U-bolt,

as long as it is rigid and of sufficient strength. Wooden structures are not recommended for mounting, as they trap

moisture (which could affect sensor performance) and their mounting rigidity degrades over time (screws/bolts

weaken and fall out or corrode).

Any style of bolt or screw may be used as long as it is steel and meets or exceeds the following:

Maximum ¼"-20 bolt or ؼ" screw (length varies with user need)

Flat washers for bolts/nuts/screws

Minimum Grade 5 (or better)

Corrosion protection for all hardware (paint, galvanize, zinc plating, etc.)

2.3

WIRING CONFIGURATIONS

The OI-6000 has several basic wiring configurations, dependent upon the desired usage and functionality intended

by the end-user. All OI-6000 units r12 to +35 Volts of wired DC power to operate. Data communication from

the device, through either the 4-20 output or the RS-485 Modbus connection, to an external location are optional.

Consult the subsequent sections of wiring instructions for pertinent information and guidelines pertaining to the

installation of your device.

CAUTION

VERIFY that the power source is disabled before beginning the following wiring steps or performing any

maintenance inside the device enclosure.

The internal components can be static sensitive. Use caution when opening the enclosure and handling

internal components.

DO NOT use any metal objects or tools to remove the terminal board from the internal system.

VERIFY that the label and color combination of the control board terminal exactly matches the

corresponding label and color combination of the power terminal.

WARNING

When securing the lid onto the device, tighten the enclosure lid by hand ONLY. Overtightening of the lid by

use of hand-tools could result in damage to the O-ring, potentially compromising the moisture seal, resulting

in an unsafe environment.

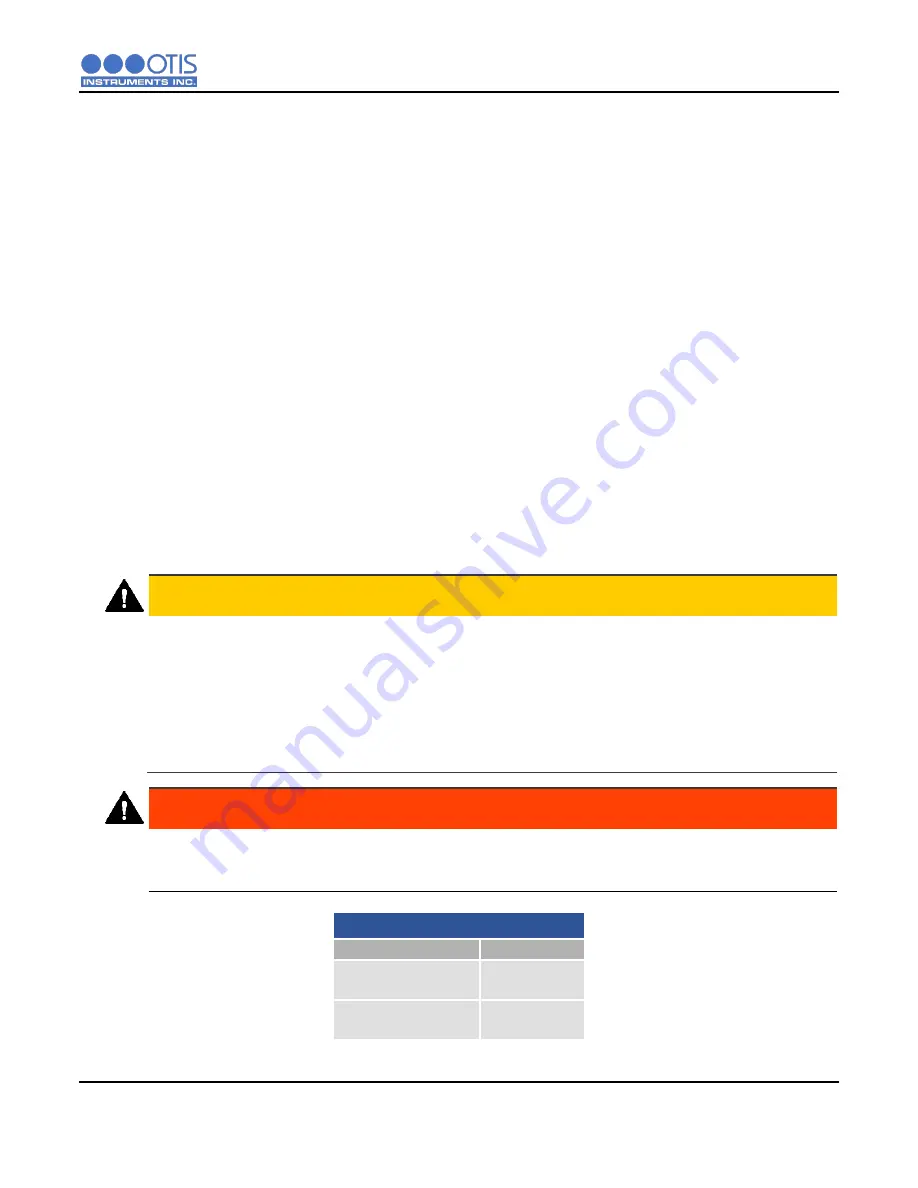

OI-6000 Terminal Block Wire Gauges

Terminal Block

Wire Gauge

Power Terminal

Relay 1 & 2 Terminal

Min: 26 AWG

Max: 14 AWG

Modbus Terminal

Fault Terminal

Min: 26 AWG

Max: 16 AWG

AWG: American Wire Gauge

Summary of Contents for GEN II OI-6000

Page 1: ......

Page 2: ......

Page 4: ......

Page 28: ...INSTALLATION AND STARTUP 22 OI 6000 X X X X O OPS_GUIDE_REV 3 1...