2-64

Installation Instructions

Installation on G4 Cabinets

External Return Bin Installation and Service Guide

/67-2038 Rev D

© 2011 Omnicell, Inc.

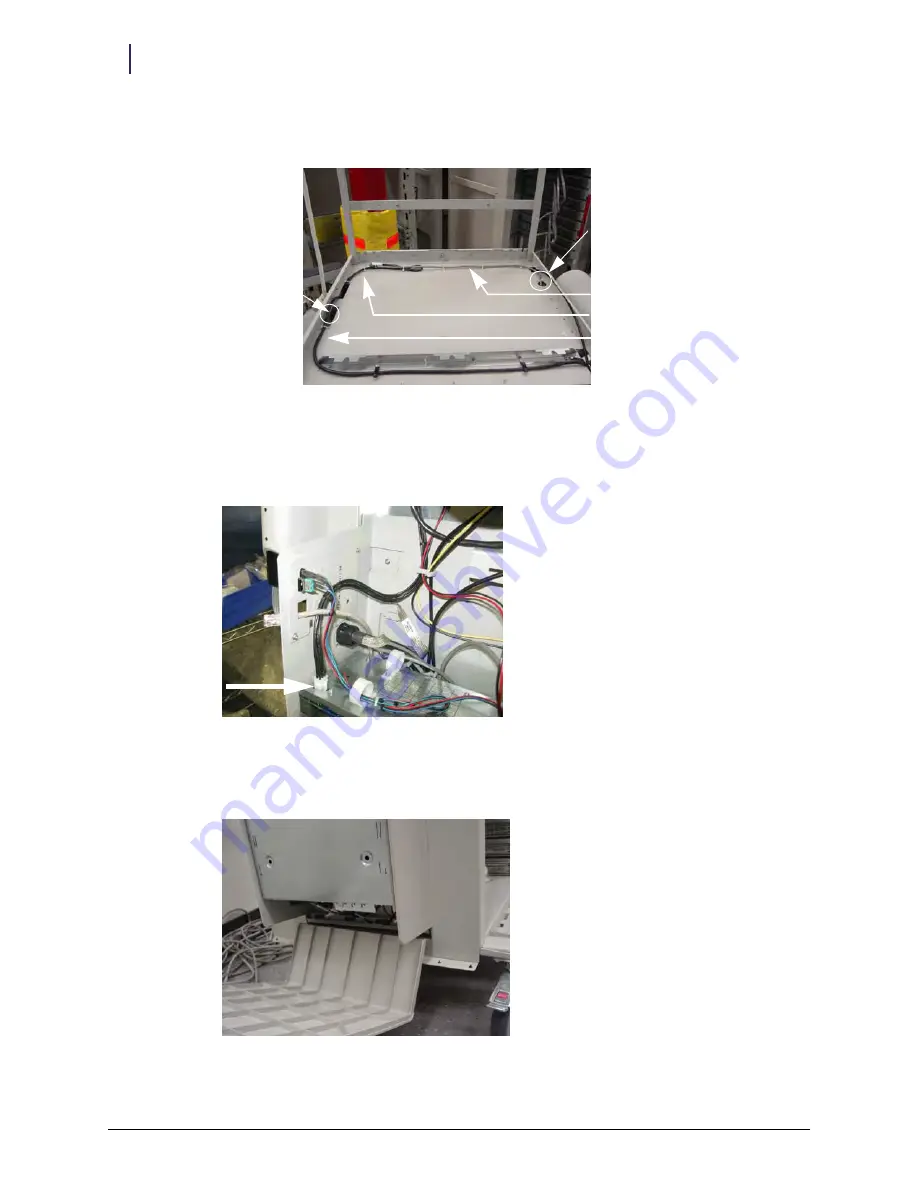

5. Route the ERB PowerCom cable and adapter cable across the top of the chassis and into the

slot for the E-box.

Figure 2-156.

ERB cable routed into E-box slot

6. Bundle excess cable lengths and secure the cables to the cover with

, using the anchors

in the chassis.

7. Connect the ERB adapter cable into the E-box.

Figure 2-157.

ERB cable connected to E-box

8. Close and lock the side cover.

a. Insert the bottom edge of the cover into the slot below the E-box.

Figure 2-158.

Reinstalling E-box cover

ERB PowerCom cable

Wireway cable

E-box slot

ERB cable slot

ERB adapter cable