MF 64

Author: Donato Gavino Murru [email protected]

Pag.

130

a

179

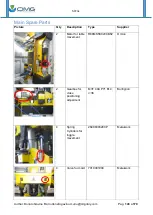

Lift the lower part of the mold and when the “T” inserts are inside the rails, push the lower part of

the mold just against the positioning blocks (if provided) at the end of rails.

Insert the water pipes inlet and outlet of the cold-water system to cool down mold and open the

valves after.

“T” insert

“T” insert under the face of mold

Push lower part of mold and

center it on the table.

Align “T” inserts with rails and slide.

Turn the Key to lock the lower part of mold.