5.2 Water Discharge Test

Before the test, make sure that the water discharge pipeline is

smooth, and check that each connection is sealed properly.

Conduct the water discharge test in a new room before the

ceiling is paved.

2. Connect the power supply, and set the air conditioner to operate in

cooling mode. Check the sound of the drain pump, and check

whether the drainage outlet is discharging water properly (based on

the length of the pipe, the discharge may occur 1 minute), and check

for water leakage at each joint.

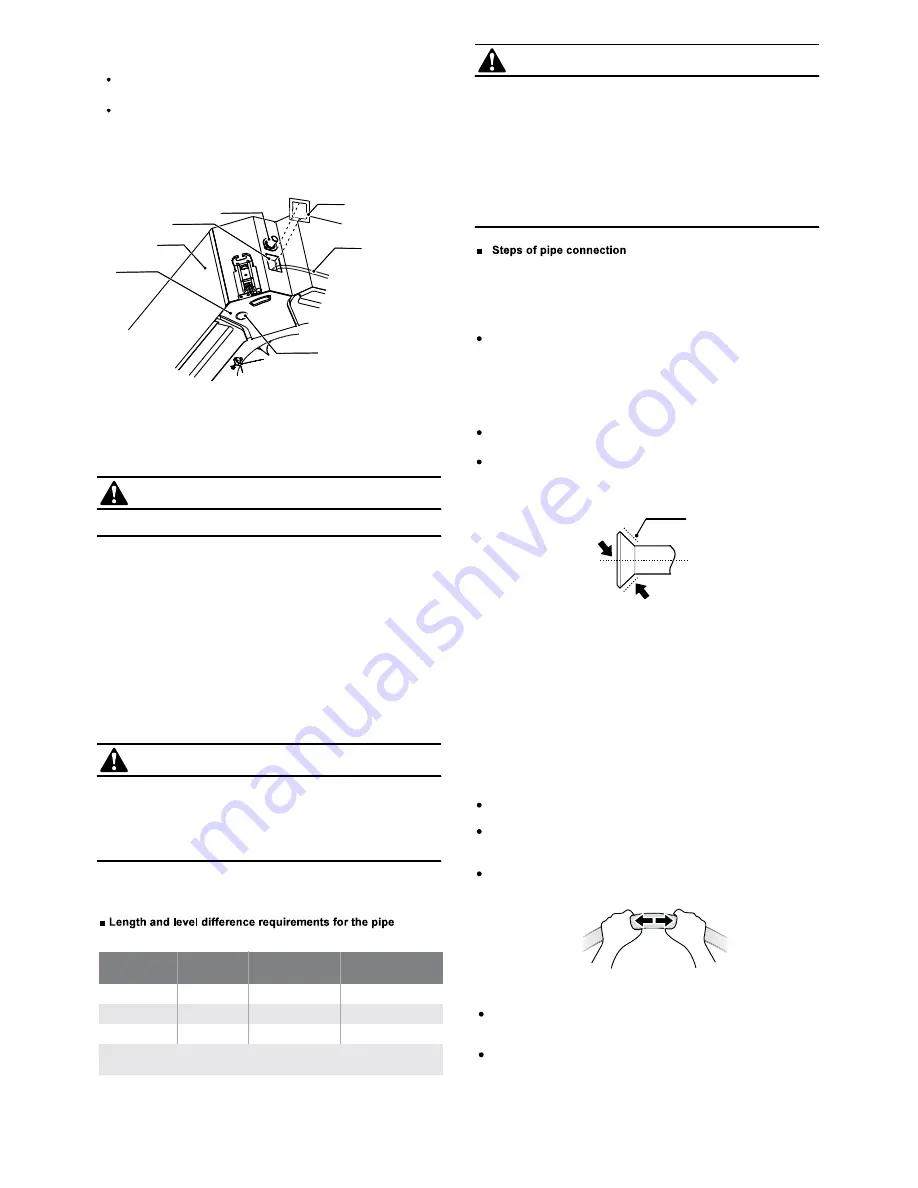

To water suction pipe

Test water outlet

Unit

Drainage pan

Water cover assembly

Water injection pipe

Water discharge trench

Faults, if any, need to be rectified in time.

The drainage plug at the bottom of the unit is used to discharge

accumulated water from the drainage pan when the air

conditioner malfunctions. When the air conditioner is operating

normally, make sure the drainage plug is properly plugged to

prevent water leakage.

3. Stop the air conditioner. Wait for three minutes, and then check if

there is anything unusual. If the water discharge piping layout is not

correct, the excessive water flow will cause the alarm indicator on the

control box to flicker. There may even be water overflowing from the

drainage pan.

4. Continue to add water until the alarm for excessive water levels is

triggered. Check if the drain pump drains water immediately. After

three minutes, if the water level does not fall below the warning level,

the unit will shut down. At this time, you need to turn off the power

supply, and drain away the accumulated water before you can start

up the unit normally.

5. Turn off the power supply, remove the water, and put the water

cover assembly back to the original place.

1. Remove the water cover assembly to connect to the test water

outlet, and use the water injection pipe to inject 2000 ml of water into

the drainage pan.

Measure the required length of the connecting pipe. Make the

connecting pipe using the following method (see the column Pipe

Connection for details).

1. Connect the IDUs before the ODU.

Bend and arrange pipes carefully without damaging the pipes

and their insulating layers.

Before tightening the flare nut, apply refrigerant oil on the outer

surface at the pipe flaring position and the conical surface of the

connecting nut (the refrigerant oil used must be compatible with

the refrigerant of this model), and screw it 3 to 4 turns with your

hand to tighten it as shown in the Fig 3-9.

When connecting or removing a pipe, use two wrenches at the

same time.

Do not put the weight of the connecting pipe on the connector of

the IDU. Otherwise, the heavy weight will deform the connector

and affect the cooling (heating) effect.

Do not bend a pipe more than 90 degrees (see the figure on the

right).

The bend should be as close as possible to the center of the

tube and the bend radius should not be less than 3.5D (pipe

diameter).

Do not bend the flexible tube back and forth more than 3 times.

When bending a pipe, cut off the required recess in the

insulation pipe at the bend and expose the pipe (wrap the bend

with a binding tie after bending).

Keep the elbow radius as much as possible to prevent flattening

or crushing. Use a pipe bender to make tight elbows.

2. The check valve of the ODU should be completely closed (e.g.

the ex-factory condition).

3. After the refrigerant pipe is connected to the IDU and ODU,

discharge the air according to the column Air Discharge. After the

air is discharged, tighten the service nut.

Precautions for flexible pipes:

Bend a thin-walled connecting pipe (see the right figure):

Unscrew nuts from the check valve in each connection, and

connect the flared tube immediately (within 5 minutes). When the

nut at the check valve is removed and placed for too long, dust

and other sundries may enter the pipeline system and cause

failures at a later time.

Fig 3-9

Apply refrigerant oil

Bend the pipe with your thumbs

connections of IDU and ODU

5.3 Connection of Connecting Pipe

Do not let air, dust, or other particles invade the pipeline system

during installation of the connecting pipes.

Install the connecting pipes only when the indoor and outdoor

units are secured.

Make sure to keep the connecting pipes dry during installation

so that no water will enter the piping system.

Connecting copper pipes must be wrapped with insulation

materials (thicker than 10mm, the thickness should be increased

if the unit is installed in a closed humid place).

CAUTION

Maximum

length (m)

Maximum level

difference (m)

Maximum number

of bends

Notes: If the height difference is greater than the allowed level

difference, it is recommended to place ODU above the IDU.

20

15

15

Product

Model

53/71

30

20

15

90/105/120

50

25

15

140/160

CAUTION

CAUTION

9