CS9360 User’s Guide

6-124

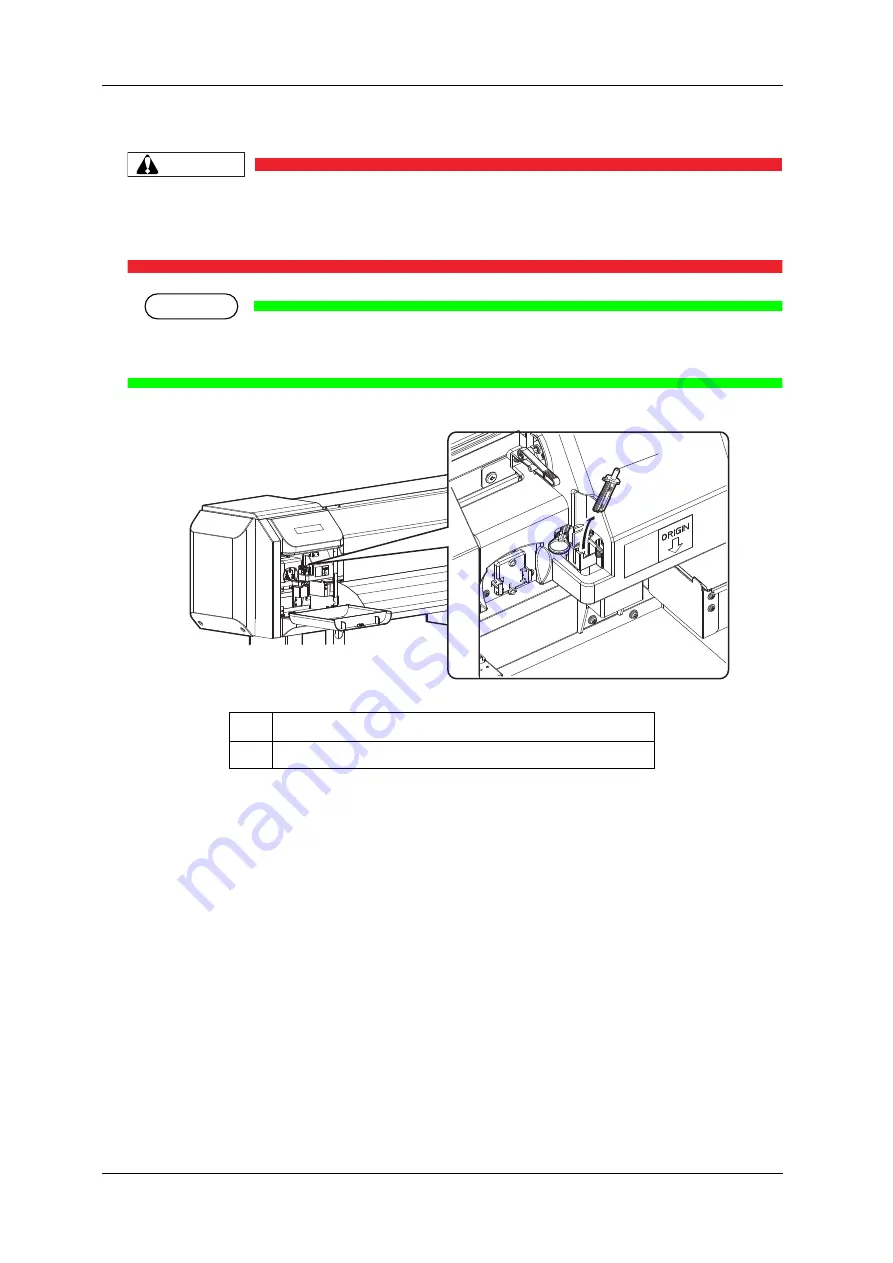

Step 6:

Remove the cutter.

CAUTION

Do not touch the blade edge. It may cause an injury.

Do not touch the cutter blade edge with a hard substance or drop the cutter.

The cutter blade may be damaged or chipped.

NOTE

Used cutter should be put in a plastic bag, etc, and dispose of it in compliance with local

ordinance and instructions of local authorities.

N°.

Name

1

Razor blade

1

Summary of Contents for CS9360

Page 1: ...Oc CS9360 Eco Solvent User s Guide AP 40811_1 0...

Page 2: ......

Page 6: ...User s Guide CS9360 6 AP 40811 Revision 1 0...

Page 16: ...CS9360 User s Guide 1 16...

Page 24: ...CS9360 User s Guide 2 24...

Page 68: ...CS9360 User s Guide 3 68...

Page 146: ...CS9360 User s Guide 6 146...