When discriminating metals as ferrous / non-ferrous, the

Target ID sometimes is not sufficient. FerroCheck™ shows

the ferrous/non-ferrous ratio of targets graphically on the

screen.

FerroCheck™ is a unique feature of The LEGEND that you will not

find on other detectors and it provides the user the

ferrous/non-ferrous ratio of the target signal to be able to identify

targets more easily.

Targets such as large iron, rusted nails, bottle caps contain both

ferrous and non-ferrous signals and these types of targets

cannot be discriminated by Target ID and audio response only.

These types of targets may generate a non-ferrous audio

response as well as a Target ID.

IMPORTANT!

Until you get experienced with this feature, it is

recommended to dig out all targets. By comparing the targets

with the FerroCheck™ graphs, users can use this feature

more productively to identify targets.

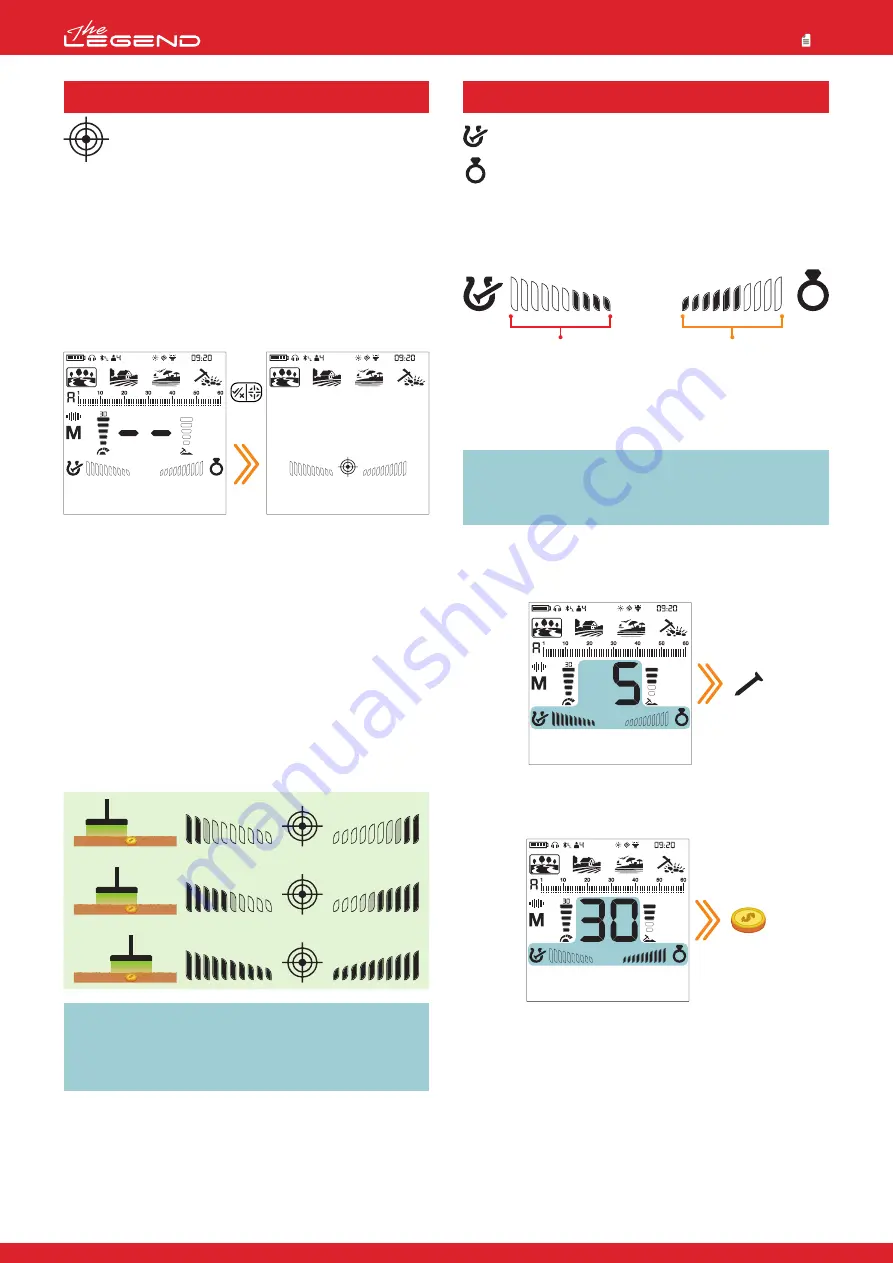

Ferrous Target

Targets with ferrous signal only will be identified as 100% ferrous

both in Target ID and FerroCheck™ as shown below:

True Non-Ferrous Target

Targets with non-ferrous signal only will be identified as 100%

non-ferrous both in Target ID and FerroCheck™ as shown below:

PINPOINT

Pinpoint is to find the center or the exact location of a

detected target.

The LEGEND is a motion detector. In other words, you are

required to move the search coil over the target or the target over

the search coil in order for the device to detect the target. The

pinpoint mode is a non-motion mode. The device continues to give

a signal when the search coil is kept stationary over the target.

When the Pinpoint & Accept/Reject Button is pressed, unused

icons are cleared from the screen. The pinpoint icon and the

FerroCheck™ bars are displayed empty.

In the pinpoint mode, the device does not discriminate metals or

provide Target IDs.

To perform pinpoint:

1. After a target is detected, move the search coil aside where

there is no target response and push the pinpoint button.

2. Keep the button pressed down and bring the search coil closer

to the target slowly and parallel to the ground.

3. Signal sound becomes stronger and changes in pitch while

getting closer to the target center and the bars in the FerroCheck™

start filling up from.

4. Mark the position which provides the loudest sound using a tool

or your foot.

5. Repeat the above procedure by changing your direction 90°.

Actions to be performed from a couple of different directions will

narrow the target area and provide you with the most exact

details of the target location.

IMPORTANT!

When a signal is received, inexperienced users,

until they get the experience to perform the procedure

mentioned above, can pinpoint by putting the search coil

down on the ground and scan over the target while pressing

the Pinpoint & Accept/Reject Button.

Long

press

FERROCHECK™

Ferrous ratio

Non-ferrous ratio

False Non-Ferrous Target

When targets such as bottle caps -although they generate a

non-ferrous Target ID- are checked by the FerroCheck™ feature,

they are identified as alloy which has ferrous (iron) content as

shown below:

The target generates a non-ferrous ID. However, it has both

ferrous and non-ferrous signal.

IMPORTANT!

For the FerroCheck™ feature to work, the

detector must receive a strong signal. Therefore, FerroCheck™

is designed to work with shallower targets.

Correct Usage of the FerroCheck™

The accuracy of the FerroCheck™ feature is directly related to

correct usage. Therefore, once you detect a target, if you want to

check whether the target is ferrous or non-ferrous with the

FerroCheck™, please pay close attention to the instructions below:

1. You MUST sweep the coil with a large angle over the target and

make wide scans. Make sure that the search coil leaves the signal

completely during the sweeps.

2. You must go around the target and swing the coil over it from

different angles, with long sweeps again.

3. The ferrous side does not need to fill up completely. More than

2 bars is enough to identify a target as an alloy containing iron

(not a true non-ferrous target).

13